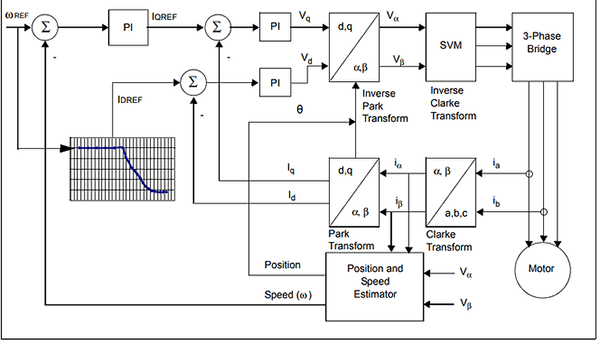

The core value of the FOC (Field-Oriented Control) algorithm lies in achieving independent regulation of motor torque and magnetic flux through coordinate transformation and decoupling control. The specific principle can be derived from the function of the module block diagram as follows:

The core logic framework of sensorless FOC control for permanent magnet synchronous motors (PMSM)

1. Decoupling control: Convert the coupled three-phase current into independent torque/magnetic flux components

The core of the FOC block diagram lies in the Clarke Transformation (from a three-phase stationary coordinate system to a two-phase stationary coordinate system) and the Park Transformation (from a two-phase stationary coordinate system to a two-phase synchronous rotating coordinate system). The essence of these two transformations is mathematical decoupling:

The three-phase stator current (Ia, Ib, Ic) is converted into two-phase stationary current (Iα, Iβ) through Clark transform.

Then, through the Parker transform, it is converted into the torque component Iq and the magnetic flux component Id in the synchronous rotating coordinate system (consistent with the direction of the rotor magnetic field).

Since Iq and Id are DC components in the rotating coordinate system, they can be adjusted separately through independent PI controllers (similar to the control of armature current and excitation current in DC motors), completely solving the problem of "torque and magnetic flux coupling" in three-phase AC motors.

22. Precise adjustment: Independent PI control of torque and magnetic flux

The independent PI controllers of Iq and Id in the block diagram are the key for FOC to achieve precise control:

Iq loop (Torque Loop) : Directly controls the motor output torque, achieving an extremely fast torque response (for example, when the load suddenly changes, Iq can be adjusted to the target value within 10ms).

Id loop (Magnetic Flux Loop) : Controls the Angle between the stator magnetic field and the rotor magnetic field (always maintained at 90°), maximizing the "torque-to-current ratio" (i.e., outputting higher torque under the same current), while avoiding magnetic saturation.

3. Sinusoidal output: Restore the decoupled component to a three-phase drive signal

After PI adjustment, Iq and Id return to the two-phase stationary coordinate system (Iα, Iβ) through inverse Parker transformation, and then generate sinusoidal three-phase voltage signals through SVPWM (Space vector PWM) to drive the inverter to output stable three-phase current:

Compared with square wave control, sinusoidal current can eliminate torque ripple (fluctuation < 1%), reduce motor vibration and noise.

Compared with scalar control (V/F control), the sinusoidal output of FOC enables the motor to maintain high efficiency (efficiency > 95%) throughout the full speed range (5% to 100% of the rated speed).

4. Dynamic response and multi-mode adaptation

The FOC block diagram also demonstrates a three-loop cascading control of "speed loop - torque loop - current loop" :

The outermost speed loop outputs a torque command based on the target rotational speed (such as that given by a potentiometer).

The intermediate torque loop (Iq loop) converts torque instructions into current instructions.

The innermost current loop (Iq and Id loops) directly controls the input current of the motor.

This structure enables FOC to support multiple scenario requirements such as torque mode, speed mode, and position mode, and has an extremely fast dynamic response capability (such as the torque step response when an elevator starts).

Summary: The irreplaceability of the FOC algorithm

FOC is the only algorithm that achieves "decoupling of torque and magnetic flux + precise PI adjustment + sinusoidal output", making it far superior to traditional control methods (such as scalar control and square wave control) in terms of performance (torque accuracy, speed regulation range), efficiency (energy saving), and reliability (low vibration, low noise), thus becoming the preferred solution for mid-to-high-end PMSM control.

免责声明: 本文章转自其它平台,并不代表本站观点及立场。若有侵权或异议,请联系我们删除。谢谢! Disclaimer: This article is reproduced from other platforms and does not represent the views or positions of this website. If there is any infringement or objection, please contact us to delete it. thank you! |