Source: GigaDevice Author: GigaDevice

In the current era of rapid technological development, sensors, as key components for obtaining information, are changing people's lives and industrial patterns at an unprecedented speed. MEMS barometric sensors, with their advantages of high precision, low power consumption and small size, are widely penetrating into many fields such as smart devices and industrial manufacturing, and their market size continues to expand.

At the ongoing Munich Shanghai Electronics Show, GigaDevice (booth 701, Hall N5) showcased a high-precision pressure sensor solution based on the GDY1122 waterproof type. This solution features a 10ATM waterproof rating and outstanding performance, making it suitable for precise pressure measurement in harsh environments. With its strong R&D capabilities, GigaDevice has built a rich and differentiated product portfolio of MEMS barometric sensors, comprehensively covering different market demands. The company continuously promotes technological innovation, has established a complete Sensor technology platform matrix, and through the implementation of the "3 highs, 1 low, 1 Excellent" strategy, constantly breaks through technological bottlenecks and drives the development trend of the industry.

A new force in air pressure perception

MEMS barometric sensors, with their significant advantages of high precision, low power consumption and small size, have been deeply integrated into various scenarios of modern life. In indoor environments, MEMS barometric sensors become invisible rulers for floor positioning, capable of capturing extremely minute atmospheric pressure differences and achieving meter-level height recognition in skyscrapers. In the field of three-dimensional positioning, MEMS barometric sensors, together with GPS and gyroscopes, form a sensor matrix, effectively filling the vertical blind spots of traditional positioning technologies. In terms of sports health monitoring, MEMS barometric sensors have also demonstrated unique application value. When climbers are climbing, the smart devices worn on their wrists can quietly transform into barometric monitors by taking advantage of their functions to predict the risk of altitude sickness in advance. The smart bracelet worn by swimming enthusiasts can also build an underwater safety alarm system with the help of this sensor.

In countries such as Japan and the United States, it is stipulated that mobile phones must have the function of locating people's height to deal with rescue in emergency situations. Therefore, MEMS barometric sensors have become standard products for mobile phones. Moreover, this configuration is gradually being adopted in more products, even including some children's watches.

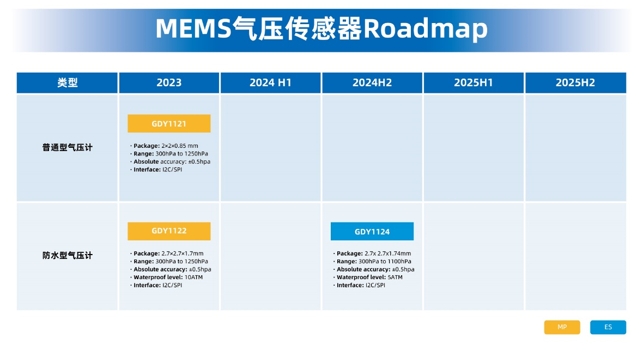

In the field of MEMS barometric sensors, GigaDevice already has a clear and forward-looking product portfolio. The standard barometer GDY1121, as the main product targeting the mobile phone market, has successfully passed the E911 test. In terms of waterproof barometer products, GigaDevice also has several differentiated products on its product portfolio. Among them, GDY1122 has been successfully mass-produced in the products of internationally renowned manufacturers, demonstrating outstanding market competitiveness. This product has a water resistance capability of up to 100 meters underwater. The GDY1124 is targeted at the mid-to-low-end wearable device market and supports water resistance up to 50 meters underwater. The two chips maintain the same core performance. The launch of GDY1124 aims to provide a more cost-effective solution for customers who are more sensitive to cost and have lower waterproof requirements. These product solutions can fully meet the diverse needs of different customers and application scenarios, whether they pursue ultimate performance in the high-end market or focus on cost-effectiveness in the mid-to-low-end market.

From energy-saving pioneers to waterproof powerhouses

The two mass-produced products of GigaDevice have fully demonstrated its innovation capabilities in the MEMS field. Among them, GDY1121 stands out with its outstanding energy efficiency performance. Its power consumption at A 1Hz sampling rate is only 3.5μA, and the typical current in the working mode is as low as 154μA, both of which are lower than the industry average. It can be called the energy-saving benchmark of micro-sensors. This product is equipped with precise pressure capture technology, with an absolute accuracy of ±0.5hPa and a relative accuracy of ±0.06hPa. The RMS noise is as low as 0.1Pa. Combined with a 24-bit high-precision ADC, it can achieve sub-pascal level data parsing capabilities, meeting the measurement requirements in harsh environments.

Its intelligent data management architecture is equipped with a 576-byte large-capacity FIFO, supports flexible interrupt function, and directly outputs the calibrated pressure value, eliminating the need for external MCU algorithm processing steps. This significantly reduces system complexity and development cycle, creating a plug-and-play sensing solution. In addition, the GDY1121 integrates a highly sensitive temperature sensor and has been successfully applied in high-reliability scenarios such as rugged mobile phones. It has passed a 48-hour stability test (deviation < 5.6Pa), verifying its all-weather stability performance.

As an enhanced version of GDY1121, GDY1122 supports a water resistance level of 10ATM, far ahead of similar products. Its package size is 2.7x2.7x1.7mm, the absolute pressure accuracy is ±0.5hPa, the relative accuracy is ±0.06hPa, and the ADC accuracy reaches 24-bit. It has a water resistance rating of up to 10ATM and can adapt to harsh environments.

Another outstanding feature of GDY1122 lies in its excellent waterproof packaging process. It adopts ceramic packaging to enhance temperature stability and stress resistance. In terms of the crucial waterproof adhesive, traditional products mostly use transparent adhesive on the outer layer. If directly exposed to sunlight, it will cause accuracy deviations. However, GDY1122 has undergone technological innovation and can maintain data stability even under direct sunlight.

Thrust testing is a classic test that simulates the mechanical thrust (such as compression or squeezing) that sensors are subjected to during installation or use to verify the anti-deformation ability of micro-mechanical structures. It can simulate scenarios such as the daily pressure that barometers in wearable devices need to withstand. The test result of GDY1122 in this item shows that the display packaging strength exceeds the 3500g specification (measured to reach 4000 to 5000g), which can meet the requirements of harsh environments.

The technical bottlenecks faced by MEMS sensors mainly focus on aspects such as the high sensitivity of the devices to stress and temperature. Due to the fact that the product is subject to the combined effects of its own measured pressure, ambient temperature and external pressure in practical applications, the absolute accuracy of the final measurement data is greatly interfered with. To ensure product performance, during the R&D process, GigaDevice carried out rigorous and meticulous verification work on the product's form factor packaging, minimizing the impact of external factors on the product.

Looking ahead to this year, GigaDevice will also focus on launching a high-end barometric sensor product, which not only features precise barometric measurement capabilities but also integrates advanced water depth measurement capabilities. The pressure measurement range of this product covers 300 to 1250hPa, which is equivalent to the standard atmospheric pressure range. The water pressure measurement can reach 300 to 4000hPa, supporting precise detection at a depth of 30 meters underwater. This product will mainly be applied in the high-end market, providing an ideal solution for customers who pursue ultimate performance.

Build a Sensor technology platform matrix

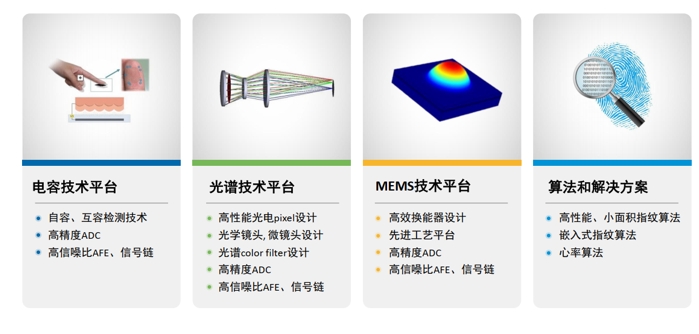

Gigadevice's goal in the sensor field is to deeply cultivate sensors, signal chains, algorithms and solutions, and become an important contributor to the entire ecosystem. To achieve this goal, GigaDevice has built four technical platforms in the Sensor business field: the capacitive technology platform, the spectral technology platform, the MEMS technology platform, and algorithms and solutions. These platforms complement each other and can provide diverse and high-performance sensor products and solutions for different industries.

Capacitance technology platform: Centered on self-capacitance and mutual capacitance detection technologies, it utilizes high-precision ADC, high signal-to-noise ratio AFE, and signal chains to achieve precise measurement and signal processing of capacitance changes. It plays a key role in fingerprint recognition for mobile phones, PCS, tablets, and touch solutions of various sizes, from large to small, by detecting changes in capacitance to identify fingerprint features or sense touch operations.

Spectral technology platform: Focusing on optical-related technologies, it covers high-performance optical-Pixel design and can accurately perceive light signals. The design of optical lenses and microlenses can optimize the transmission and focusing of light. Spectral color filter design to achieve the screening and processing of different spectra. Combining high-precision ADC, high signal-to-noise ratio AFE and signal chain, it can efficiently convert optical signals into precise electrical signals and process them, which can be used in scenarios such as the detection of physiological indicators in the field of optoelectronics.

MEMS technology platform: Sensor development is based on MEMS technology, and advanced process platforms, high-precision ADC, high signal-to-noise ratio AFE, and signal chains are utilized to ensure the high precision and stability of the sensors. The products are widely applied in fields such as floor height detection, auxiliary positioning, mobile phone height position navigation, and motion detection of smartwatches/bracelets.

Algorithm and solution platform: Develop high-performance algorithms for different sensors and application scenarios, such as high-performance, small-area fingerprint algorithms and heart rate algorithms, etc. embedded fingerprint algorithms. It also provides customized application solutions for various industries, combining sensor data with actual application requirements to enhance the practicality and functionality of products and meet the application needs of multiple fields.

Through the "3 Highs, 1 Low, 1 Excellent" strategy (the "3 highs" refer to high integration, high precision, and high sensitivity; "1 low" refers to low power consumption; "1 Excellence" refers to the development of algorithms and industry application solutions with outstanding performance. Gigadevice is leading the technological innovation of MEMS sensors, that is, by adopting miniaturized integrated design to integrate multi-dimensional perception and data processing, and relying on precise processes and intelligent algorithms to achieve stable measurement and high sensitivity in complex environments. The innovative low-power architecture significantly reduces energy consumption and supports long-term monitoring of mobile terminals. Build a full-chain technology ecosystem and accelerate product launch through pre-set algorithms, standardized calibration and scenario-based solutions.

免责声明: 本文章转自其它平台,并不代表本站观点及立场。若有侵权或异议,请联系我们删除。谢谢! Disclaimer: This article is reproduced from other platforms and does not represent the views or positions of this website. If there is any infringement or objection, please contact us to delete it. thank you! |