Source: ON Mei Author: On Mei

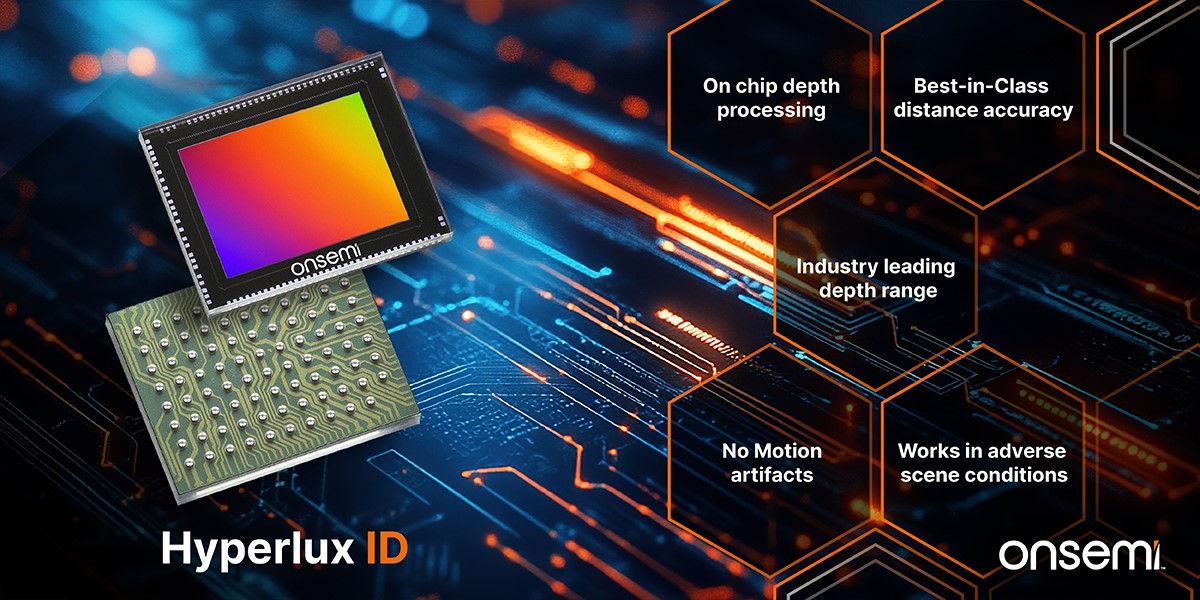

Shanghai, China - March 12, 2025 - onsemi (NASDAQ: ON) introduces its first real-time, indirect Time of flight (iToF) sensor, Hyperlux? The ID series enables high precision long distance measurement and 3D imaging of fast moving objects. The Hyperlux ID series features On's new proprietary global shutter pixel architecture and built-in storage to capture the full scene while taking real-time depth measurements. This innovative approach goes beyond the limitations of standard iToF sensors to achieve depth perception up to 30 meters, four times the size of standard iToF sensors, and in a smaller form factor. In addition, the sensor family generates both black and white images and depth information. By combining these two outputs, the sensor family can provide a comprehensive view of the environment without having to configure separate sensors for visual and depth data.

As a result, the Hyperlux ID series enables simplified design and industry-leading ultra-depth perception, working in dynamic scene conditions and capturing fast-moving objects, which were not possible before.

With the widespread application of automation and robotics in the industrial sector, fast and efficient access to high-precision depth information has become critical to improving productivity and safety in complex environments. However, until now, iToF sensors have been limited in their application due to their limited ranging range, poor performance in poor lighting conditions, and inability to calculate depth for moving objects.

With the ability to make precise measurements of moving objects and high-resolution images, the Hyperlux ID series will help reduce errors and downtime, optimize processes in manufacturing systems, and thus reduce operating costs. In addition, the Hyperlux ID series is suitable for consumer applications such as facial recognition, gesture detection and 3D video conferencing.

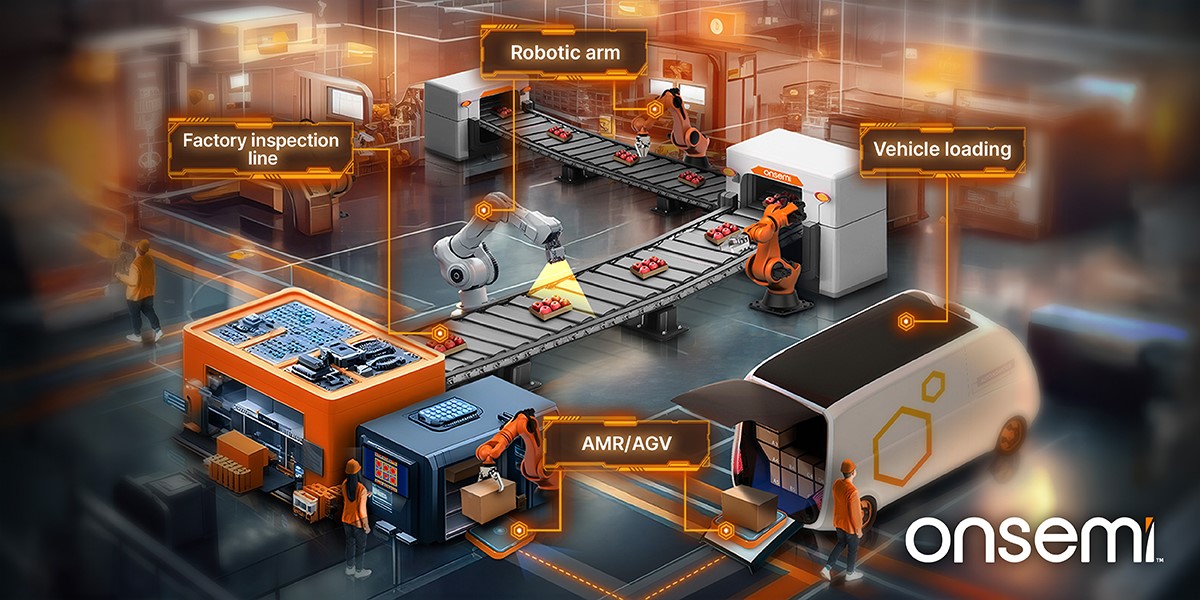

The Hyperlux ID series is ideal for use in a wide range of industrial environments, such as:

Automation and robotics: Improve safety on the factory floor by detecting objects for better navigation and obstacle avoidance.

Manufacturing and Quality control: Ensure that products meet quality standards by measuring the volume and shape of objects and detecting defects.

Logistics and Material Handling: Optimize warehouse management and transportation processes by measuring the position, size and proportion of pallets and goods.

Agriculture and Planting: Monitor crop growth and health by measuring plant height, detecting disease, and optimizing irrigation and fertilization processes.

Access control systems: Provide highly refined, highly accurate facial recognition for payment terminals, home and business entry systems, etc.

The Hyperlux ID sensor family incorporates global shutter architecture and iToF technology for accurate and fast depth perception. The iToF technique senses depth by measuring the phase shift of reflected light emitted from one or more vertical cavity surface emitting lasers (VCsels). The proprietary pixel architecture enables the sensor to simultaneously capture and store four different phases of light in a single exposure, instantly capturing a full scene and improving the accuracy of depth measurements. In addition, global shutter technology synchronizes all sensor pixels with the VCSEL, significantly reducing ambient infrared noise from other light sources. The built-in deep processing capability also outputs real-time results without the need for expensive external memory and high-performance processors.

The Hyperlux ID series includes a 1.2 megapixel global shutter and a 3.5μm backlit (BSI) pixel sensor. The AF0130 model also has built-in processing capabilities that make integration easier and reduce system costs. For customers who want to integrate their own depth inspection algorithms, AF0131 is available, adding greater flexibility to their systems.

About onsemi

onsemi (NASDAQ: ON) is committed to driving disruptive innovation and building a better future. The company focuses on megatrends in the automotive and industrial end markets, accelerating innovation and innovation in segments such as electronic vehicle functionality and automotive safety, sustainable power grids, industrial automation, and 5G and cloud infrastructure. On offers a highly differentiated portfolio of innovative products and smart power and intelligent perception technologies to solve the world's most complex challenges and lead the way in creating a safer, cleaner and smarter world. On is a Fortune 500 company and is included in the NASDAQ 100 Index and the S&P 500 Index.

免责声明: 本文章转自其它平台,并不代表本站观点及立场。若有侵权或异议,请联系我们删除。谢谢! Disclaimer: This article is reproduced from other platforms and does not represent the views or positions of this website. If there is any infringement or objection, please contact us to delete it. thank you! |