Introduction

Many motion control applications adopt permanent magnet DC motors. Because compared with AC motors, the control system of DC motors is easier to implement. Therefore, when it is necessary to control speed, torque or position, DC motors are usually adopted.

There are two commonly used types of DC motors: brushed motors and brushless motors (also known as BLDC motors). As the name suggests, brushed DC motors are equipped with brushes, which can make the motor commutate and rotate. Brushless motors, on the other hand, replace the mechanical commutation function with electronic control.

Many applications can use both brushed DC motors and brushless DC motors. Both types of motors are based on the same principle of attraction and repulsion between coils and permanent magnets. Each has its own advantages and disadvantages and can be selected specifically according to application requirements.

Brushed DC motor

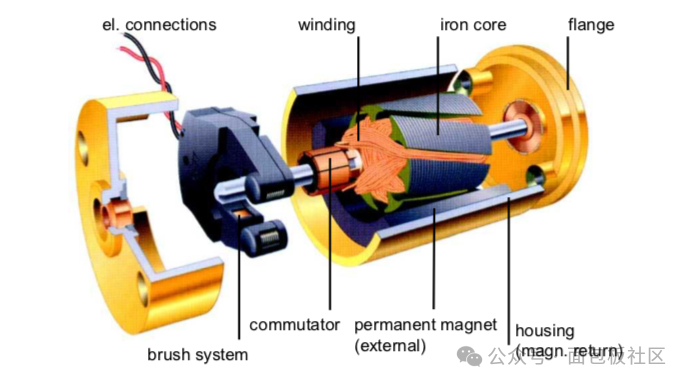

Brushed DC motor (Image source: maxon Group)

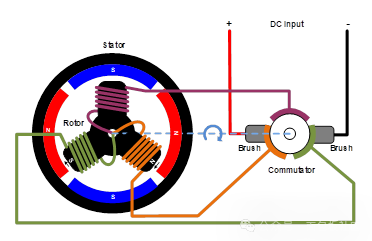

As the rotor rotates, the commutator constantly connects and disconnects different rotor windings, causing the rotor coils to be constantly attracted and repelled by the fixed magnets of the stator, thus making the rotor rotate.

There is mechanical friction between the brushes and the commutator in brushed motors, and since they are electrical contacts, lubrication is usually impossible. Therefore, the brushes and commutators are subject to mechanical wear throughout the entire service life of the motor, which will eventually lead to the motor being unable to operate. However, many brushed motors (especially large ones) have replaceable brushes, which are usually made of carbon and can maintain good contact even after wear. These motors all require regular maintenance. But even if there are replaceable brushes, the commutator will eventually wear out to the point where the motor must be replaced.

To drive a brushed motor, a direct current voltage needs to be applied across the brushes to make the current flow through the rotor windings and thus rotate the motor. If a brushed motor only needs to rotate in one direction in an application and does not require speed or torque control, there is no need to drive electronic devices at all. In this type of application, the motor can be run or stopped simply by turning on and off the DC voltage. This is very common in low-cost applications such as electric toys. If reverse rotation is required, it can be achieved through a bipolar switch.

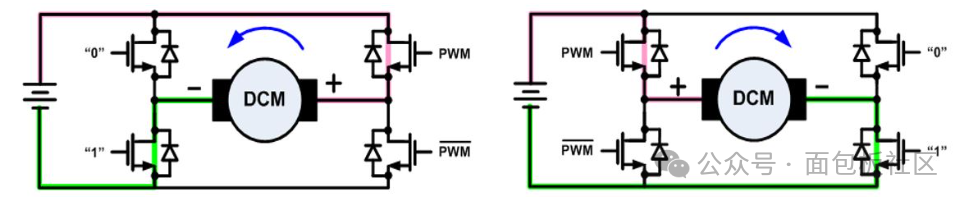

If speed, torque and direction need to be controlled, an "H-bridge" composed of electronic switches (transistors, IGBTs or MOSFETs) is used to drive the motor to rotate in any direction. The voltage applied to the motor can be of any polarity, which causes the motor to rotate in different directions. The speed or torque of the motor can be controlled by modulating the width of the switch pulse.

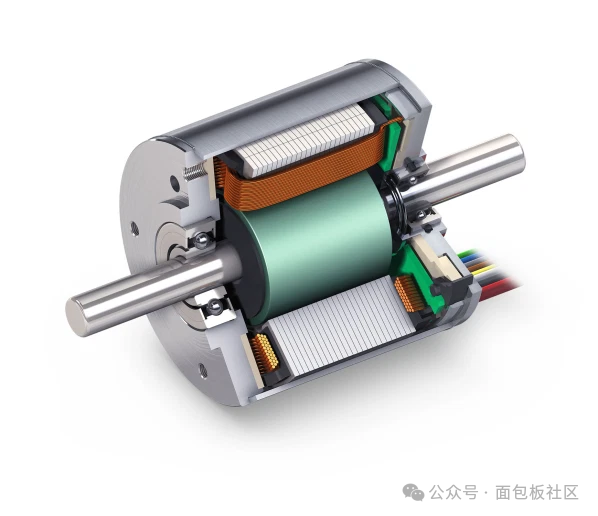

Brushless DC motor

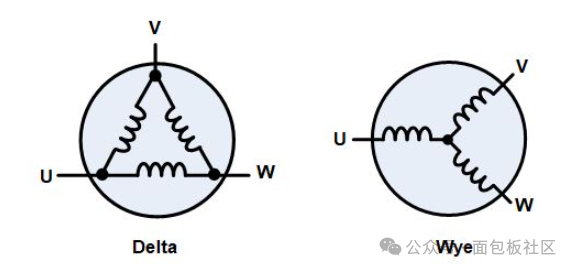

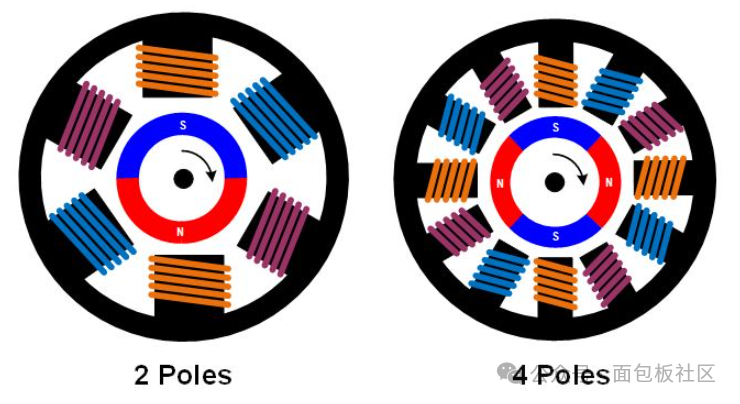

Three-phase motors can be constructed with different magnetic configurations, which are called magnetic poles. The simplest three-phase motor has two magnetic poles: the rotor has only one pair of magnetic poles, one N pole and one S pole. Of course, there can also be more magnetic poles, which requires configuring more magnetic parts in the rotor and adding more windings in the stator. The more magnetic poles there are, the higher the performance will be, but fewer poles can achieve a higher speed.

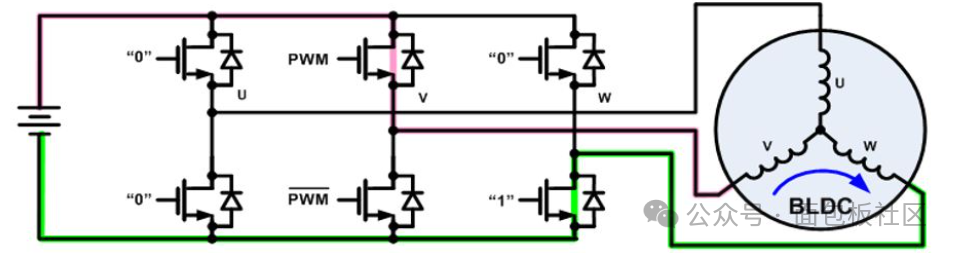

To drive a three-phase brushless motor, each phase of the three-phase windings needs to operate at either a high potential or a low potential depending on the position and state of the rotor. For this purpose, three "half-bridge" drive circuits are usually adopted to achieve the drive, and each drive circuit consists of two switches. Depending on the required voltage and current, the switch can be a bipolar transistor, IGBT or MOSFET.

There are many drive technologies that can be adopted for three-phase brushless motors, among which the simplest ones are called trapezoidal wave drive, square wave drive or 120-degree commutation control. Trapezoidal commutation is somewhat similar to the commutation method used in DC brushed motors: at any given time, one of the three phases is grounded, one is disconnected, and the other is connected to the power supply voltage. If speed or torque need to be controlled, pulse width modulation can be used to connect to the phase of the power supply voltage. Because the phase suddenly switches at each commutation point and the rotation of the rotor is constant, the torque will change to some extent as the motor rotates, which is called torque fluctuation.

To improve performance, other commutation methods can also be adopted. The sinusoidal or 180-degree commutation method can always drive the current of all three motor phases. The controller controls the drive, enabling the three-phase brushless motor to generate sinusoidal current in each phase, and the phase shift between each phase is 120 degrees. This drive technology can minimize torque fluctuations as well as noise and vibration to the greatest extent, and is usually used in high-performance or high-efficiency drives.

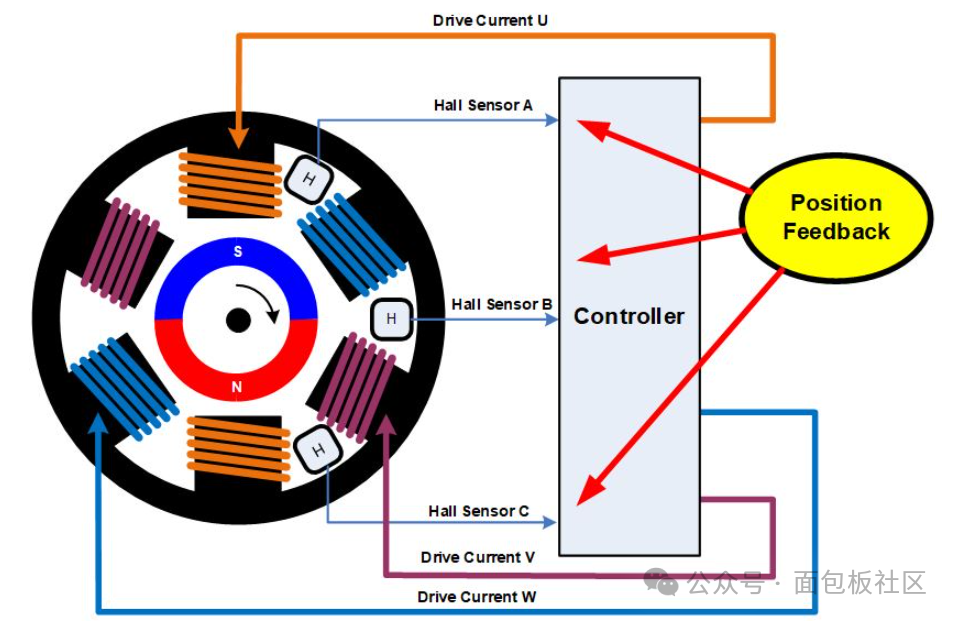

To rotate the magnetic field appropriately, controlling electronic devices requires knowing the physical position of the magnets on the rotor relative to the stator. Usually, this position information is obtained through a Hall sensor installed on the stator. When the magnetic rotor rotates, the Hall sensor picks up the magnetic field of the rotor. The driving electronic device utilizes this information to make the current flow sequentially through the stator windings to rotate the rotor.

Three Hall sensors are adopted, and trapezoidal commutation can be achieved through simple combinatorial logic without the need for complex control electronic devices. Other commutation methods (such as sinusoidal commutation) require more complex control electronic devices and usually microcontrollers.

In addition to using Hall sensors to provide position feedback, there are many other ways to determine the rotor position without sensors. The simplest method is to monitor the counter electromotive force on the undriven phase to sense the magnetic field relative to the stator. There is another more complex control algorithm, known as field-oriented Control (FOC), which calculates the position based on rotor current and other parameters. FOC usually requires a powerful processor to perform many calculations quickly, so this method is much more expensive than the simple trapezoidal control method.

The advantages and disadvantages of brushed motors and brushless motors

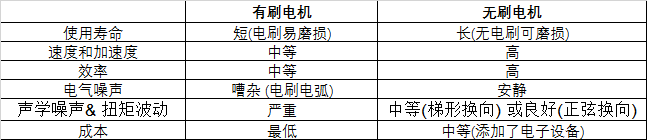

The following table summarizes the main advantages and disadvantages of the two types of motors. Depending on the application requirements, you may prefer to choose a brushless motor.

Service life

如As mentioned earlier, one of the disadvantages of brushed motors is that there is mechanical wear on the brushes and commutators. Carbon brushes, especially consumables, are stipulated in many motor maintenance plans to be replaced regularly. The soft copper of the commutator will also be gradually worn by the brushes and eventually cause the motor to fail to work. However, brushless motors have no moving contacts, so this kind of wear does not exist.

Velocity and acceleration

The rotational speed of a brushed motor is limited by the mass of the brushes, commutator and rotor. At extremely high speeds, the contact between the brush and the commutator will become unstable, and the brush arc will increase. Most brushed motors also use laminated iron cores in the rotor, which gives them a large moment of inertia and limits the acceleration and deceleration rates of the motor. The adoption of high-performance rare earth magnets on the rotor c

Electrical noise

Brushes and commutators form an electrical switch. When the motor rotates, the switch opens or closes, and a large amount of current flows through the inductor rotor winding, generating an arc at the contacts. These arcs will generate a large amount of electrical noise and couple into sensitive circuits. Adding capacitors or RC buffers to the brushes can reduce the arc to a certain extent, but the instantaneous switching of the commutator still generates some electrical noise.

Acoustic noise

Brushed motors are "hard-switching", that is to say, the current suddenly moves from one winding to another. As the windings are connected and disconnected, the generated torque varies with the rotation of the rotor, resulting in torque fluctuations. Brushless motors can control the winding current to gradually transition from one winding to another, which reduces torque fluctuations. Torque fluctuation is the mechanical pulsation of energy on the rotor, which can cause vibration and mechanical noise, especially more severe when the rotor speed is low.

Cost

Brushed motor technology is very mature and the manufacturing cost is also very low. Brushless motors have a higher total cost than brushed motors because they require more complex electronic devices. However, because there are no brushes and commutators, it is easier to manufacture than brushed motors. Brushless motors are becoming increasingly popular, especially in large-scale applications such as automotive motors. In addition, the continuous decline in the cost of electronic devices (such as microcontrollers) also makes brushless motors more attractive.

Summary

Due to the continuous decline in cost and better performance, brushless motors are becoming increasingly popular. However, for some applications, brushed motors remain the best choice.

From the application of brushless motors in automobiles, we can know that by 2020, most of the motors (such as pumps and fans) that run while cars are in motion have been converted from brushed motors to brushless motors to enhance their reliability. The reduction in on-site failure rate and maintenance requirements fully compensates for the increased costs of brushless motors and their driving equipment.

On the other hand, those motors that are not frequently operated (such as those for moving electric seats and electric Windows) still mainly use brushed motors. Because throughout the entire life cycle of a car, the total operating time of these motors is very short and they are unlikely to malfunction.

As the cost of brushless motors and related electronic devices continues to decline, brushless motors are gradually penetrating the applications dominated by traditional brushed motors. Another example in the automotive industry is that the seat adjustment motors in high-end models have been replaced with brushless motors because they produce less noise.

免责声明: 本文章转自其它平台,并不代表本站观点及立场。若有侵权或异议,请联系我们删除。谢谢! Disclaimer: This article is reproduced from other platforms and does not represent the views or positions of this website. If there is any infringement or objection, please contact us to delete it. thank you! |