Selection of low-power motor drive schemes and driver ics

Motor drive, as the actuator link in the entire closed loop of factory automation in Industry 4.0, its performance directly affects the performance of the entire closed loop. Therefore, Industry 4.0 has put forward higher performance and functional requirements for motor drives, such as faster response speed, higher bandwidth, more precise position and speed control, as well as richer network interconnection functions, etc. For motors in different application scenarios, we should select the corresponding drive schemes. Simply put, for high-power motors, a drive with low internal resistance and a large allowable current should be selected, while for low-power motors, a drive with lower power can be chosen. Dc low-power motors are widely used in various devices such as household appliances, industrial control systems, and computers. The more conventional method is to adopt PWM control. There are two common driving methods:

1. Adopt integrated motor driver chips;

Second, MOSFETs and dedicated gate driver chips are adopted.

According to the degree of integration, there are three motor driver solutions: system-on-chip (SoC) solution, integrated control solution (ICS), and gate driver solution.

The SoC solution integrates DC-DC, gate drivers, controllers, inverters, feedback/protection, etc. onto a single chip. It has a high degree of integration, is suitable for space-constrained applications, and is simple and easy to use.

Compared with the SoC solution, the ICS solution does not integrate an inverter, and thus can support a wide range of power through external MOSFETs, making it suitable for applications with higher power and offering greater flexibility.

The gate driver solution only integrates DC-DC, gate driver and feedback/protection. Since the controller and power devices are both external, it has flexibility.

The gate-level drive solution has a wide range of applications in non-automotive markets due to its flexibility and traditionality, such as in low-power scenarios like fans, power tools, and massage chairs. There are isolation gate-level drive products and non-isolation gate-level drive products.

Shuming Semiconductor offers highly reliable gate-level drivers, with products covering a working voltage range of 200V and 600V. Customers can choose from various drive currents as well as half-bridge and full-bridge designs.

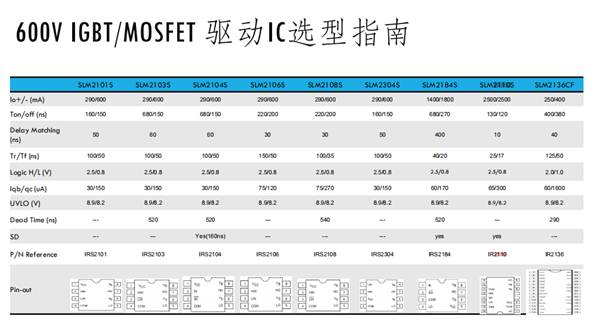

Among the non-isolated gate-level driver products of Shiming, the 200V IGBT/MOSFET half-bridge driver ics include SLM2001, SLM2003, SLM2004, and SLM2005. The 160V IGBT/MOSFET three-phase full-bridge driver IC is SLM7888. 600V IGBT/MOSFET half-bridge driver ics SLM21XX and SLM2304S, as well as three-phase full-bridge driver IC SLM2136. Non-isolated door-level drive products feature high reliability and wide compatibility, as well as a broader driving capacity.

Isolated half-bridge gate drivers can be used in many applications, ranging from isolated DC-DC power modules that require high power density and efficiency to solar inverters where high isolation voltage and long-term reliability are crucial, and so on. The new series of compatible optocoupler isolated single-channel gate drivers, SLM34x, from Shuming, compared with traditional optocoupler gate drivers, features a series of advantages such as low latency, low pulse width distortion, strong common-mode transient immunity, long service life, wide operating temperature range, wider operating voltage range, stronger negative pressure resistance at the input end, and can be applied in variable frequency, servo, UPS, etc. It is applied in different fields such as induction heating.

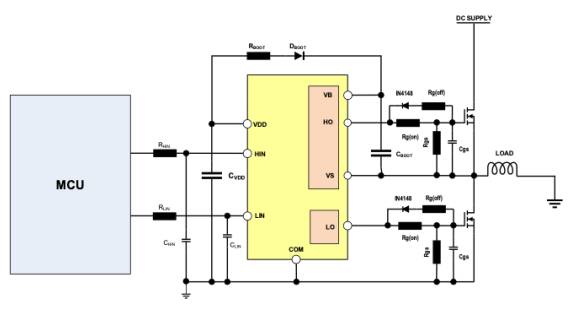

Figure 2

Today's content mainly involves the non-isolated half-bridge drive products of Shu Ming. As shown in Figure 2, it is a typical half-bridge application circuit.Non-isolated half-bridges have been widely applied in fields such as motor control, switching power supplies, and industrial automation. Several non-isolated half-bridge drive products have a wide range of applications. For instance, the SLM2106S is used in hair dryers, while the SLM2101S has successfully entered markets such as ceiling fans, bladeless fans, blenders, fans, and warm air blowers. SLM2XX has occupied a considerable market share in the white goods market. Three-phase drive products such as SLM2136 also have a certain market share in industrial control applications like treadmills, industrial sewing machines, and water pumps. SLM7888 has established a firm foothold in the market of power tools like electric vehicles and Angle grinders. Today, we mainly focus on the application of Shiming's half-bridge driver ics in the drive of low-power motors.

In the design of the motor drive circuits for various low-power applications mentioned above, the main considerations are:

1. The rotation direction and speed of the motor. For unidirectional motor drive, it is sufficient to directly drive the motor with a high-power transistor or MOS. When the motor needs to rotate in both directions, an H-bridge circuit composed of four power components can be used. By changing the direction of the current flowing into the motor, the motor's rotation direction can be altered. If speed regulation is required, switching components such as transistors and MOS can be used to achieve PWM(Pulse Width Modulation) speed regulation. PWM control is usually used in conjunction with bridge drive circuits to achieve speed regulation of DC motors. The motor's rotational speed is proportional to the voltage across the motor, and the voltage across the motor is directly proportional to the duty cycle of the control waveform. Therefore, the motor's speed is proportional to the duty cycle. The larger the duty cycle, the faster the motor rotates. When the duty cycle α = 1, the motor's rotational speed

2. For the motor drive circuit with PWM speed regulation, the following performance indicators mainly need to be considered when choosing the drive IC:

2.1) Output current and withstand voltage determine the power of the motor that the circuit can drive.

2.2) Efficiency: Save power while reducing the heat generation of the drive circuit. It can start from ensuring the switching working state of power devices and preventing common-state conduction (when it is necessary to involve H-bridges).

2.3) Impact on the control input terminal: Whether to use an isolated driver IC.

2.4) Impact on power supply.

2.5) Reliability. In system applications, since the gate driver connects the logic control unit and the power conversion unit, the stability of the gate driver chip plays a crucial role in the reliability of the entire system.

Therefore, it is necessary to adopt different driving schemes for different application scenarios.

Figure 3-1

Figure 3-2

In low-power application scenarios, gate-level driver schemes are widely used, and it is extremely important to select the appropriate gate-level driver IC. MOSFET has a fast switching speed and low on-resistance, and thus occupies half of the motor drive circuits. To enable MOSFETs to fully exert their performance in applications, the drive circuit is indispensable. In applications, MOSFETs typically operate in the bridge topology mode as shown in Figure 1. Since the reference point of the drive voltage of the lower bridge MOSFET is ground, it is relatively easy to design the drive circuit. However, the drive voltage of the upper bridge fluctuates with the phase line voltage. Therefore, how to drive the upper bridge MOSFET well becomes the key to the success of the design. Compared with full-bridge drive, half-bridge drive chips have been widely used in MOSFET drive circuits due to their advantages such as easy design of drive circuits, fewer peripheral components, strong driving capacity, high reliability and flexibility. The half-bridge gate-level driver chip of Shuming is a good choice. The two main parameters of the gate-level driver IC are: withstand voltage and drive current. As shown in Figure 3, both SLM2101 and SLM2106S mentioned earlier have a withstand voltage of 600V and a driving current of 290/600mA. (There is parasitic capacitance between the gate and source of the MOSFET. The on and off processes of the MOSFET are the charging and discharging processes of the capacitor.) If the drive circuit of the MOSFET cannot provide sufficient peak current (input/output current), the switching speed of the MOSFET will be reduced. Therefore, it is crucial to select different driver ics to drive motors based on different products. These are MOSFET and IGBT driver ics with high and low side reference output channels, high voltage resistance, and high speed. The logic input is compatible with standard CMOS or LSTTL output, and the logic voltage can be reduced to 3.3V. The output driver is characterized by a driver cross-conduction with a high pulse current buffer stage design. The floating channel can be used to drive N-channel power MOSFETs or IGBTs configured on the high side, with a withstand voltage of up to 600V and an on-off time of 220 ns/200 ns. The on-off time of SLM2101S is 160 ns/150 ns.

Disclaimer: This article is reproduced from other platforms and does not represent the views or positions of this website. If there is any infringement or objection, please contact us to delete it. thank you! |