This article will delve deeply into brushless DC motors, abbreviated as BLDC motors. We will have a detailed understanding of its definition, working principle, driving methods and wide range of application fields.

BLDC motors have occupied an indispensable position in modern drive technology, and their popularity is increasing day by day in multiple fields such as household appliances, the automotive industry, and industrial automation. Although brushed DC motors once dominated the range below the kilowatt level, with the advancement of power electronics and microprocessing technologies, small brushless DC motors have significantly improved in terms of cost performance, gradually expanding their application scope.

So, what is a brushless (BLDC) motor? It is similar to the traditional brushed DC motor, but the core difference lies in the commutation method. Brushless motors input current into the stator through the drive circuit to achieve electronic commutation without the need for physical brushes. Unlike conventional brushed DC motors that transfer current to the rotor through carbon brushes, the current of brushless motors is directly delivered to the stator coils. This design not only eliminates the friction noise and wear problems caused by carbon brushes, but also significantly extends the service life of the motor.

The Construction and Design of Brushless DC Motors

The core difference between brushless DC motors and brushed motors lies in their commutation methods. Brushless motors abandon the traditional mechanical commutator and instead use electronic switch circuits for commutation. This design makes the brushless DC motor essentially look like a synchronous motor, that is, the magnetic fields generated by the stator and rotor rotate at the same frequency.

Brushless motors typically come in three different configurations: single-phase, two-phase, and three-phase. Among them, three-phase BLDC motors are the most widely used. Next, we will delve into the internal structure of the BLDC motor and gain a detailed understanding of its working principle and the functions of each component through cross-sectional diagrams.

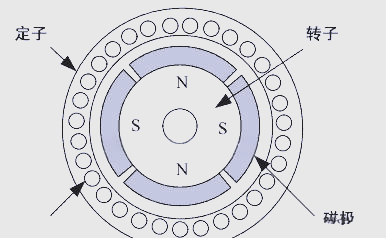

The main components of a brushless motor include the stator and rotor. The structure of the stator is similar to that of an induction motor, composed of stacked silicon steel sheets and equipped with axial grooves for easy winding. It is worth noting that the winding design in brushless motors is somewhat different from that of traditional induction motors.

Typically, a BLDC motor is composed of three stator windings, which are connected in a star or "Y" shape and have no neutral point. In addition, the stator winding can be further classified into trapezoidal current-driven and sinusoidal current-driven motors according to the coil type.

In a trapezoidal current-driven motor, both the driving current and the back electromotive force present trapezoidal waveforms, which are different from the waveform characteristics of a sinusoidal wave-driven motor. This type of motor is often applied in the fields of automotive and robotics technology, especially in hybrid vehicles and robotic arms, with a rated voltage typically of 48V or less.

Let's take a look at the rotor part. The rotor of a motor is usually composed of permanent magnets, which are mostly rare earth alloy magnets, such as neodymium (Nd), samarium cobalt (SmCo), and an alloy of neodymium ferrite and boron (NdFeB). Depending on the specific application requirements, the number of poles of the rotor may vary, usually ranging from 2 to 8, and the North Pole (N) and South Pole (S) are alternately placed. The following shows three different arrangements of magnetic poles, among which the most common one is that the magnets are placed on the outer periphery of the rotor.

The second configuration is called an electromagnetic embedded rotor, in which rectangular permanent magnets are embedded in the core of the rotor. In the third case, the magnet is directly inserted into the core of the rotor.

Position sensor (Hall sensor)

Since there are no brushes in brushless motors, their commutation process is achieved through electronic control. In order for the motor to rotate smoothly, the stator windings must be energized in a specific sequence, and the determination of this sequence requires knowing the real-time position of the rotor, that is, the location of the rotor's north and south poles.

Typically, Hall sensors (operating based on the Hall effect principle) are used to detect the position of the rotor and convert it into an electrical signal. In most BLDC motors, three Hall sensors are used, which are embedded in the stator to monitor the position changes of the rotor in real time.

The output level (high or low) of the Hall sensor depends on the current position of the rotor's North Pole - whether it is close to the South Pole or the North Pole. By integrating the output results of the three sensors, it is possible to precisely determine which group of stator windings should be energized.

Overview of Working Principle

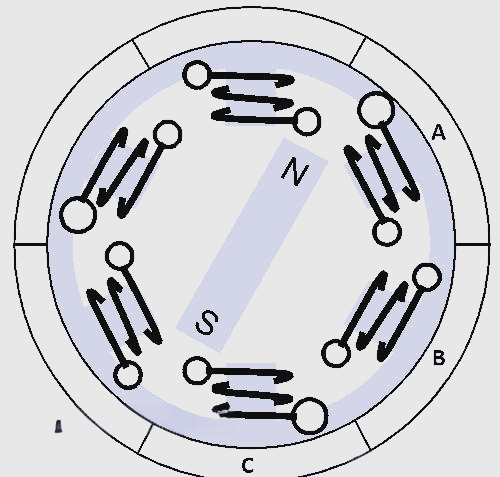

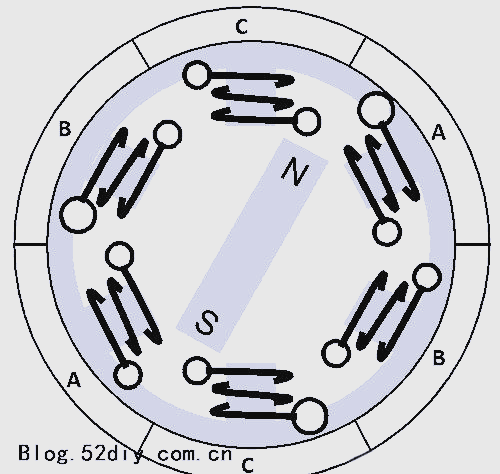

When understanding the working principle of A brushless motor, we can imagine that there are three windings set in it: A, B and C. For the sake of explanation, we use a single magnet instead of the actual rotor for demonstration.

When current passes through a coil, a magnetic field is generated, and the direction of the magnetic field lines depends on the direction of the current. Based on this principle, if current is passed through coil A, it will generate A magnetic field and attract the rotor magnets, causing the rotor magnets to slightly shift clockwise and align with A. Then, if the current flows through coils B and C in sequence, the rotor magnets will rotate continuously in a clockwise direction

To enhance efficiency, we can adopt a clever approach: designing a single coil in an opposite winding manner to generate a double attraction. Furthermore, if two coils are energized simultaneously, one coil will attract the magnet while the other will repel it, which can further enhance the efficiency. During this process, the third coil remains idle.

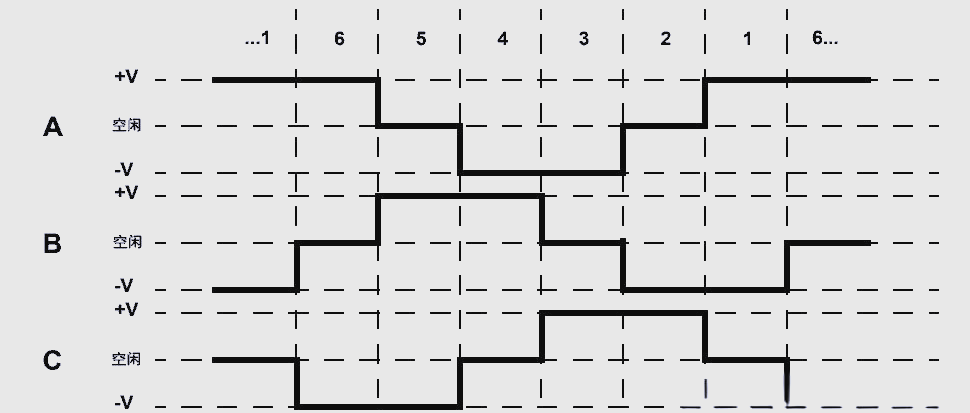

To ensure that the rotor magnet can complete A full 360-degree rotation, we can flexibly apply six different combinations of coils A, B and C, which are clearly displayed in the following timing diagram.

According to the aforementioned time sequence diagram, we can clearly see that at any given moment, there is always one phase being positive, one phase being negative, and the third phase being in an idle state (or floating state). This flexible phase sequence control, combined with the input of Hall sensors, provides us with two switch phases, thereby achieving precise driving of brushless DC motors.

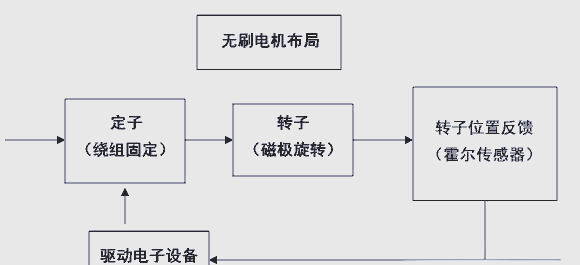

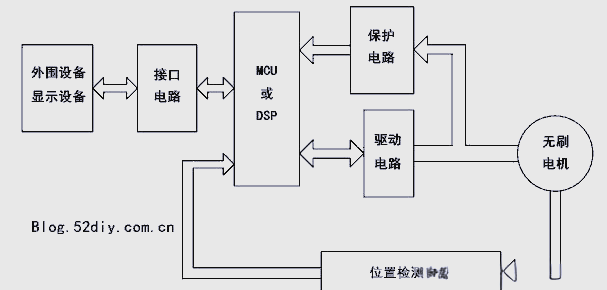

In brushless motors, the stator and rotor play core roles, while the drive circuit is the key to ensuring the smooth operation of the motor. The block diagram of a typical brushless DC motor control or drive system is as follows:

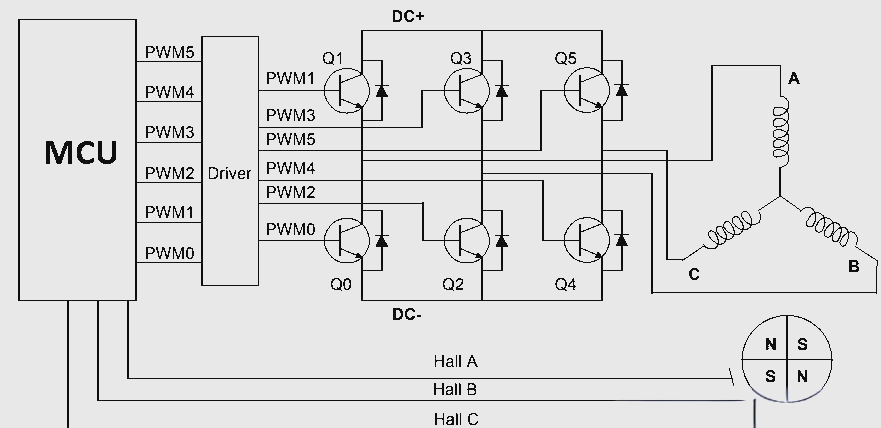

This drive circuit, often referred to as the electronic speed controller system or simplified as ESC, has a typical configuration of a full-bridge drive circuit. It contains an MCU with PWM output and six MOSFETs serving the three phases of the stator winding. In addition, the feedback and power-related components of the Hall sensor are also important parts of this system.

Through programming the MCU, the timely switching of MOSFETs can be achieved based on the data provided by the Hall sensor.

The significant advantages of brushless motors

Brushless motors achieve steering through electronic commutation. Compared with traditional brushed DC motors, they have the following significant advantages:

●No wear (thanks to the brushless design)

● High efficiency"

● Excellent speed and torque characteristics

●It is more durable

●It operates quietly with extremely low noise

●Higher rotational speed

Brushless DC motors have a wide range of applications, covering multiple fields.

免责声明: 本文章转自其它平台,并不代表本站观点及立场。若有侵权或异议,请联系我们删除。谢谢! Disclaimer: This article is reproduced from other platforms and does not represent the views or positions of this website. If there is any infringement or objection, please contact us to delete it. thank you! |