The importance of insulation resistance

Insulation resistance plays a crucial role in maintaining the integrity of the motor electrical system. The insulating materials inside the motor, such as winding insulation layers and cable insulation layers, can prevent accidental electrical contact and leakage of current to the outside of the casing. Over time, environmental factors, temperature fluctuations and operating pressure sources can reduce this insulation performance, leading to a decline in performance. In extreme cases, it may even cause catastrophic failures.

The Megger test is specifically designed to measure the resistance of insulation layers, which helps identify potential problems before they escalate. By evaluating insulation resistance, engineers can gain a thorough understanding of the overall health of the motor and predict potential faults. Regular megohmmeter testing is an active approach that can prevent unexpected shutdowns, extend motor life and enhance the overall system reliability.

Handheld Meggers

The portable and user-friendly handheld megohmmeter is suitable for routine insulation resistance testing. They are typically used in field applications where mobility is of critical importance. Even today, these instruments usually include crank handles and analog displays, without the need for batteries.

Electric Meggers

The electric megohmmeter is also equipped with additional functions such as automatic voltage regulation and data recording. These instruments are suitable for more comprehensive tests and are usually used in laboratory or workshop environments.

Digital megohmmeter

Digital megohmmeters provide readings and are usually equipped with functions such as data storage, Bluetooth connection and programmable test sequences. They are ideal choices for in-depth insulation resistance analysis.

High voltage manager

For high-voltage applications, dedicated high-voltage megohmmeters are adopted. These instruments can generate test voltages of several thousand volts, making them suitable for testing large motors and high-voltage systems.

How to manage the motor

The Megger test involves applying a high-voltage direct current potential to the motor insulation system and measuring the resulting current. This test provides a quantifiable measurement of insulation resistance, which is usually expressed in hundreds of megohms or even gigahms.

Standard multimeters are not suitable for this application because the voltage applied by the battery will not be able to provide the current that can even be measured within the working range of a standard ohmmeter (usually only reaching tens of megohms).

To conduct a megohmmeter test on the motor, please follow the following general steps:

Prepare the motor: Before starting the test, please ensure that the motor is powered off and properly isolated. Disconnect the motor from the power supply and release any stored electrical energy (many 1-phase AC motors have a starting capacitor). Disconnection or the motor starter can easily cut off the power supply.

Select Megger instruments: Choose the appropriate megohmmeter instrument based on the rated voltage of the motor. Meggers offer a variety of voltage ranges to choose from. Selecting the correct voltage is crucial for obtaining accurate results.

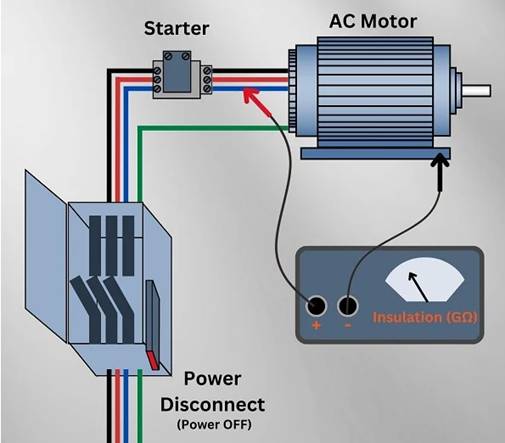

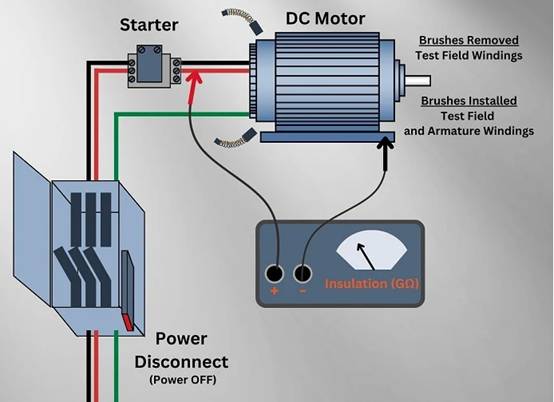

Connect the Megger: Connect the lead of the megohmmeter to the motor input terminal. The positive lead is connected to the motor winding, while the negative lead is connected to the motor frame or ground. This configuration allows the megohmmeter to measure the insulation resistance from the winding to the ground. Figures 3 and 4 respectively demonstrate the correct layout of the megohmmeter test for AC and DC motors in the form of charts.

Record and analyze the results: Record the insulation resistance value displayed on the megohmmeter. The higher the resistance value, the better the insulation integrity. Compare the obtained values with the specifications of the motor or industry standards to assess the insulation condition.

Explain the results: Analyze the results under the operating conditions of the motor. A significant decrease in insulation resistance may indicate moisture entry, contamination or insulation failure. Based on the investigation results, further investigation or corrective measures may be required.

The application tested by Megger

Although megohmmeter testing is crucial for proper motor maintenance, it is a universal diagnostic technique applicable to various industries. Some other applications include:

Transformer test

The transformer is a key step in the distribution process. The Megger test is used to evaluate the insulation resistance of transformer windings to ensure their reliable and safe operation.

Cable testing

The Megger test is used to evaluate the insulation integrity of power cables. This is particularly important in industries where cable failures can lead to significant disruptions and safety hazards.

Switchgear controls power flow. Regular megohmmeter tests should be conducted to ensure the insulation resistance of its components, prevent electrical faults and ensure the safety of operators.

Generator test

Whether used in power plants or backup systems, generators must be tested with a megohmmeter to verify the insulation resistance of their windings and detect potential faults.

Control panel test

Megger tests are conducted on the control panel and distribution board to ensure the insulation resistance of the circuit and promote the safety and reliability of the control system.

What does Megger for the motor mean

Insulation resistance testing, often referred to as megohmmeter testing, is a fundamental aspect of maintaining the reliability and performance of motors and related electrical systems. By regularly assessing insulation integrity, engineers can identify potential problems before they escalate, thereby preventing costly downtime and equipment failures.

The movement process of the motor involves applying a high-voltage direct current potential and measuring the resulting current. With the use of specialized megohmmeter instruments ranging from handheld devices to high-voltage megohmmeters, this diagnostic technique has become accessible and efficient.

Megger testing is applicable to various industries, ranging from motor and transformer testing to cable and switchgear evaluation. Its initiative allows for preventive maintenance, which is conducive to the overall reliability of the electrical system.

免责声明: 本文章转自其它平台,并不代表本站观点及立场。若有侵权或异议,请联系我们删除。谢谢! Disclaimer: This article is reproduced from other platforms and does not represent the views or positions of this website. If there is any infringement or objection, please contact us to delete it. thank you! |