Harness the power of electronics to help shift away from fossil fuels

In order to achieve carbon neutrality, people are developing and utilizing a variety of technologies that help to move away from fossil fuels, such as information processing technology, battery technology, semiconductors, system technology and motor technology. In order to use advanced technologies to create and effectively utilize new energy sources, peripheral technologies optimized for new technologies are also needed. Capacitors, inductors, module components, sensors and other new technical requirements will also emerge.

In the previous issue, we introduced "the importance of using SiC/GaN power semiconductors to improve power conversion efficiency, capacitors, inductors and other passive component technology advances". Batteries are becoming more and more important to achieving carbon neutrality, and here we will explain the battery management system (BMS) and the electronic components used in them, which are essential to keeping them healthy and safe for long term use.

There are several technologies that are suddenly getting attention for global warming countermeasures, typical of which are solar/wind power generation, electric vehicles (EVs), power semiconductors, and fuel cells. Among these technologies, the battery is an electrical component that has long been important and widely used, and whose importance has increased dramatically in recent years.

Batteries, once used in toys and flashlights, are now an essential source of power in portable devices such as laptops and smartphones. However, with the gradual electrification of hitherto fossil-fuel-burning machines and equipment and the gradual expansion of the use of renewable energy sources, new uses for batteries are expanding rapidly. More than ever, people are eager to introduce high-performance, highly reliable and safe batteries.

For example, the electrification of mobile devices that use a very powerful engine as a power source/heat source, as electric cars, electric ships and aircraft do, requires very advanced batteries. All of the following high-level requirements need to be met: large capacity for longer continuous service time, high input/output for fast charging and discharging from low power to high power, long life cycle without deterioration even after repeated charging and discharging, and high safety for use in a variety of temperature, vibration and shock conditions.

The batteries required for EV and ESS show the trend of large capacity, high voltage and long life.

However, even for batteries used in new scenarios such as electric vehicles, the basic structure and materials used are not much different from traditional batteries used in smartphones. From the perspective of capacity, power, life and so on, the most easy-to-use battery - lithium-ion secondary batteries have been used without major improvements.

The operating voltage of each cell (the smallest component unit of the battery) of a lithium-ion secondary battery is about 4V when fully charged and about 2V after discharge. Lithium-ion secondary batteries used in smartphones operate at the same voltage. In addition, the batteries equipped in the newly launched electric vehicles achieve a capacity of about 26Ah per cell. The capacity of each cell in a smartphone is about 3Ah, and the battery in an electric car is indeed a bit large, but the battery that powers a heavy machine like an electric car can still be said to be relatively small.

In fact, the motor of the electric vehicle is driven by a high-voltage power supply of 400V to 800V, and in order to obtain a practical driving range, the battery capacity needs to be equipped with a large capacity of more than 50kWh. By combining more than 1,000 cells and arranging them in series and parallel, the battery specifications of electric vehicles are realized. A high-voltage, large-capacity battery that combines a certain number of cells is called a module, and a battery that further combines multiple modules is called a battery pack.

In order to use this method of combining small cells into large batteries, there is a problem that needs to be solved first.

In general, the capacity and input/output characteristics of each cell will vary depending on the material and manufacture. Moreover, with the progress of repeated charging and discharging, its ability to withstand the stress from the environment such as charging and discharging also has individual differences, so the individual differences between cells show an increasing trend. These individual differences have a significant impact on the overall life and output characteristics of modules and battery packs composed of many cells. This is because the characteristics of modules and battery packs are determined by the cells used that have the worst performance and ability to withstand environmental stresses. In general, the ambient temperature of each cell, the voltage and current when charging and discharging all fluctuate (called "stress intensity"), so the lower the resistance to stress, the higher the degree of deterioration. Especially if the capacity is insufficient or the power is lost due to overcharge (discharge), overheating, internal short circuit and other reasons, it may cause the vehicle to be unable to control or drive, and even cause accidents.

BMS is a key system for efficient use of batteries

In this context, in order to maintain the performance and safe use of modules and battery packs composed of multiple cells for a long time, it is necessary to create a working environment that can reduce the deterioration of each cell to a small amount. In order to achieve this purpose, the control system that undertakes to closely monitor and control the movement and status of each cell is the battery management system (BMS).

In BMS, the movement and status of each cell is continuously monitored with high precision and resolution. To monitor the movement and status of the cell, sensors that monitor voltage, current, temperature and leakage are used. Moreover, the charge and discharge are controlled and balanced so that the characteristics are as uniform as possible, so as to compensate for slight mismatches and imbalances in the unit of cells and modules. This maximizes the life and performance of modules and battery packs and ensures safety.

Moreover, the battery specifications and the range of use specified by the design are compared with the collected data through software control in the microcomputer and:

1. Charge and discharge control to prevent overcharge and overdischarge resulting in cell deterioration and damage safety;

2. Charge and discharge control to prevent dangerous overcurrent;

3. Temperature management for safe and smooth operation;

4. Calculate the remaining battery power (SOC);

5. Equalization of battery voltage (called battery balance) in order to improve battery range and service life as much as possible.

In addition, if abnormal conditions such as overcharging or overheating are detected, an alarm is sent to other on-board systems and a notification is sent to the control circuit with the function of disconnecting the output power, thereby preventing accidents.

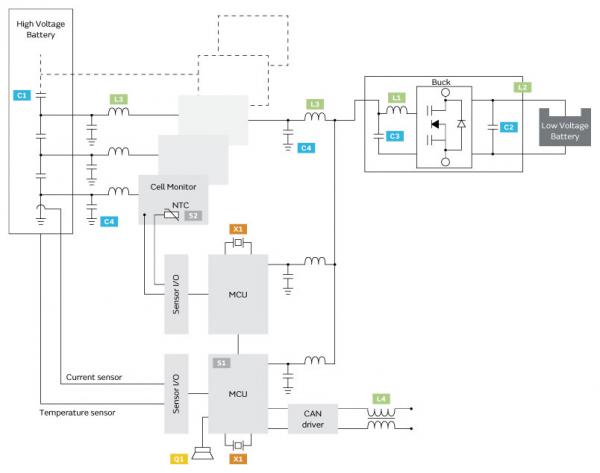

The performance of a BMS depends on the variety and precision of its built-in control functions. However, to achieve high performance, the main premise is that the sensors that detect the movement and state of the cell and the many electronic components used in the BMS circuit have high precision (Figure 3). In addition, due to the large number of cells that need to be monitored, the BMS circuit composition itself becomes very complex, requiring smaller and lighter sensors and components.

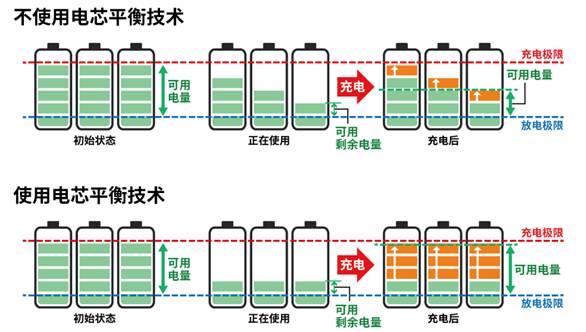

The important function of BMS - cell balance technology, there are two ways:

One is passive: use the discharge switch to force the high-voltage cell to discharge, and convert the capacitance difference between it and the low-voltage cell into heat to achieve voltage equality.

The other is the active way: the current flows between adjacent cells with unbalanced capacity and voltage to equalize the charging state of the cell. In order to exhaust the potential capacity of the battery, an active approach is needed.

In order to exhaust the potential capacity of the battery, an active approach is needed.

The performance of a BMS depends on the variety and precision of its built-in control functions. However, to achieve high performance, the main premise is that the sensor that detects the movement and state of the cell and the many electronic components used in the BMS circuit have high precision (figure below). In addition, due to the large number of cells that need to be monitored, the BMS circuit composition itself becomes very complex, requiring smaller and lighter sensors and components.

Trends: Wireless BMS and AI BMS

In BMS to date, the actions and states of each cell are inferred by comparing the data collected by the sensors with the pre-input rules and control ranges. People are now considering introducing technology that allows artificial intelligence (AI) to learn the trend of electrochemical phenomena of batteries and make more accurate guesses. It is expected that the AI BMS technology will be able to predict cell performance in fast charging and detect cell deterioration as soon as possible.

In addition, in recent years, wireless BMS (wBMS), which introduces wireless control lines between modules and between BMS, has received much attention. It reduces the number of cables that span between modules, thus reducing weight and making it easier to wire in hard-to-reach locations. When applied to BMS for electric vehicles, it is said that approximately 10m of cables can be reduced per vehicle as well as the connectors and transformers used when wired up. Moreover, it can also be equipped with a battery cell in the spare space, thereby increasing the battery capacity. However, compared with wired connections, the environment of the signal transmission path is unstable, and the risk of failure will increase.

There are already moves to apply wBMS to electric vehicles and large energy storage systems (ESS). To implement wBMS, wireless technology with high reliability and low latency is needed. Semiconductor manufacturers developing wireless ics will in most cases recommend the use of specific standard wireless technologies, most of which use the 2.4GHz ISM band wireless.

Multiple small and highly reliable wireless modules may be used in batteries for electric vehicles and energy storage systems. With the development of wireless modules, the range of applications that can be applied to wBMS may be further expanded.

免责声明: 本文章转自其它平台,并不代表本站观点及立场。若有侵权或异议,请联系我们删除。谢谢! Disclaimer: This article is reproduced from other platforms and does not represent the views or positions of this website. If there is any infringement or objection, please contact us to delete it. thank you! |