Hall components in brushless motors has always been one of our main business areas, at present, most of the brushless motors on the market are using Hall components to achieve commutation with the controller. So how exactly does a Hall element work in a motor? Why do you need at least three Hall components in a brushless motor?

Brushless DC motor is a new type of mechatronics motor developed on the basis of brushless DC motor. Instead of traditional physical carbon brush commutation Hall element, the sensor is used for digital signal commutation. This can avoid excessive wear of the carbon brush during high-speed operation, greatly extend the service life of the brushless motor, and can be externally controlled, which has made breakthrough progress compared with the brushless motor in terms of performance and convenience of control. There are many kinds of sensors, of which the Hall sensor is the most common type of brushless DC motor. We can find that most DC brushless clicks on the market have at least three Hall element sensors built in. Why should a brushless DC motor have at least three Hall sensors built in?

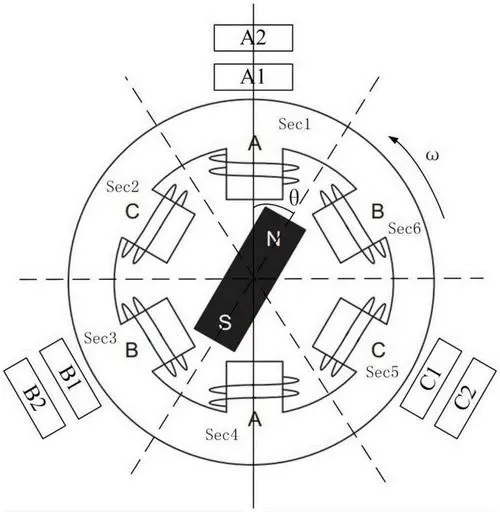

As shown in the figure above, the front solenoid is luring the permanent magnet and the back solenoid is pushing the permanent magnet. But we all know that if the magnetic pole of the coil does not change, then the magnetic pole will remain stationary when it reaches the permanent magnet, just like two magnets are drawn together, so the magnetic pole of the coil should change frequently as it rotates. Who changed the pole of the signal coil? It's a Hall sensor. The Hall sensor can sense the position of the rotor permanent magnet and report the donkey's position to the stator coil controller in time, and the controller can control the coil current in the stator based on this information. In this way, the brushless motor rotates.

In short, in order to be able to rotate, there must always be an Angle between the magnetic field of the stator coil and the magnetic field of the rotor permanent magnet. The process of rotor rotation is the process of rotor magnetic field direction change. In order to make the two magnetic fields have an Angle, the magnetic field direction of the stator coil must be changed to a certain extent. Three Hall sensors is the minimum number that can keep the brushless motor rotating, and the number of Hall sensors can be increased to increase the speed accuracy of the brushless motor.

免责声明: 本文章转自其它平台,并不代表本站观点及立场。若有侵权或异议,请联系我们删除。谢谢! Disclaimer: This article is reproduced from other platforms and does not represent the views or positions of this website. If there is any infringement or objection, please contact us to delete it. thank you! |