With the advent of the digital intelligence wave, global competition is gradually focusing on the integration of embodied intelligence and vertical scenarios. A robot revolution empowered by AI is opening the curtain on industrial transformation.

At the Spring Festival Gala in 2025, 16 Unitree H1 humanoid robots from Hangzhou Yushu Technology danced on the same stage with 16 dancers from Xinjiang Arts Institute, presenting a series of complex dance movements.

The technical foundation of the robot's core system

What is a robot? The answer to this question is being redefined. Traditional industrial robots are like "mechanical puppets", relying on preset programs to perform fixed actions, while modern robots have already acquired a complete closed-loop capability of "perception - decision-making - execution".

MLCC (Multilayer Ceramic Capacitor), as a core passive electronic component, has permeated into six key modules of modern robot architectures, playing an irreplaceable role:

Control system: MLCC is used to decouple the power supply of the main control chip to ensure that the robot's motion planning algorithm runs in real time without delay.

Drive system: The bus capacitor of the servo motor inverter needs to adopt high-voltage MLCC, which can withstand pulse voltages above 200V to filter the motor drive.

Communication module: Realizes RF front-end filtering and power supply voltage stabilization.

Power management system: Suppression of transient voltages it bears and energy storage buffering.

Human-computer interaction system: Controls the coupling of audio signals and the stability of camera signals.

Bionic system: used for controlling the high-frequency response and stability of signals.

The demand for MLCC from different types of robots in diverse environments

With the iterative optimization of AI algorithms and the popularization of edge computing architectures, robots are evolving from single-function executors to intelligent terminals with environmental perception and autonomous decision-making capabilities.

This technological leap not only reshapes the application boundaries of robots but also imposes performance requirements on the core passive component MLCC, such as high frequency (5GHz+), low loss (ESR), and wide temperature range (-55 ° C to 150 ° C +).

PART.01

Each industrial robot requires 1,000 to 5,000 MLCCS. Due to its harsh working environment, there is an urgent need for highly reliable MLCCS to ensure the stable operation of the equipment under complex working conditions.

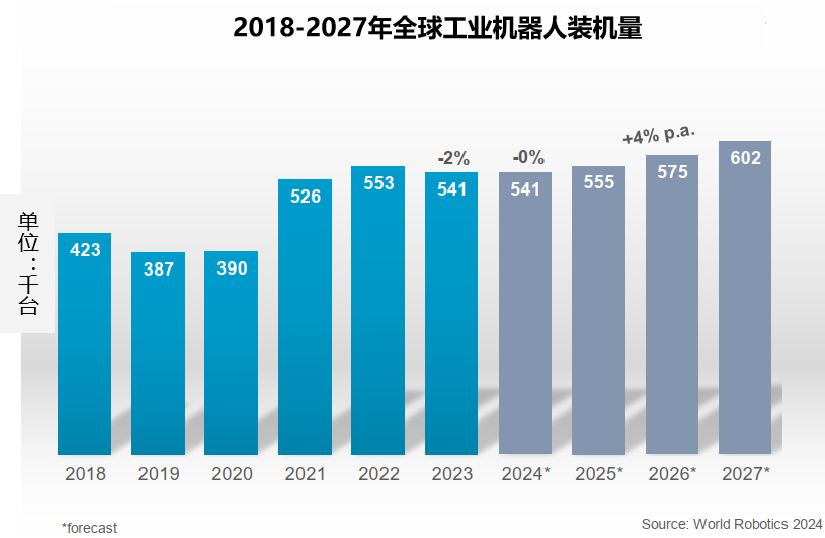

In recent years, the global installation volume of industrial robots has continued to rise and has exceeded 500,000 units for several consecutive years. From 2018 to 2023, the compound growth rate is 5%. According to the International Federation of Robotics (IFR), the installed base of process robots is expected to exceed 600,000 units by 2027.

PART.02

Consumer robot

From intelligent cleaning to early education, consumer robots are integrating into modern life in diverse forms.

Consumer robots such as sweeping robots and educational robots need to strike a balance between miniaturized design and high-frequency data processing, which leads to the usage of MLCCS in a single machine reaching 500 to 4,000.

To meet the miniaturization demands of consumer robots, MLCCS in 0402/0201 packages account for over 70%, thus making the focus on high capacity and miniaturization the main development direction of MLCCS in this field.

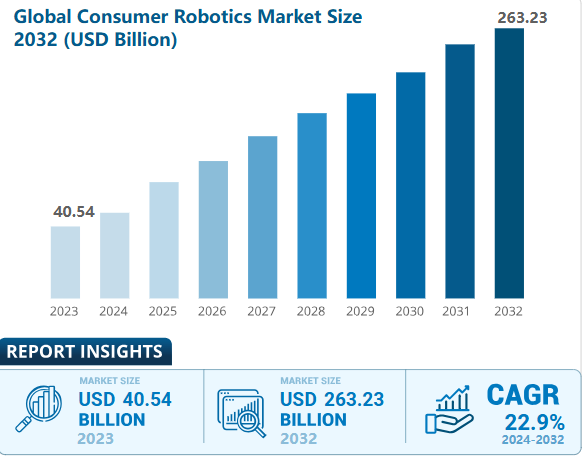

Mainly cleaning robots, compared with industrial robots, have a wider range of service targets and a larger market size, and are an important driving force for the growth of the robot industry. Since 2023, the installation volume of consumer robots has exceeded 500,000 units for three consecutive years, with a compound annual growth rate of 10%, demonstrating a vigorous development trend.

PART.03

Special robots

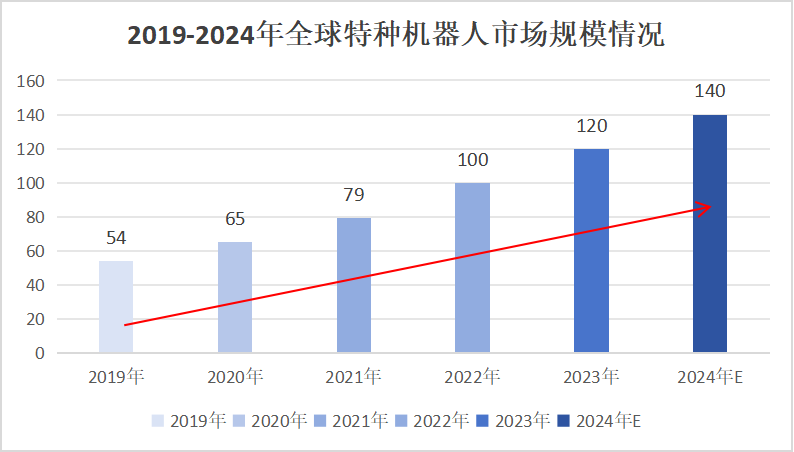

Due to the special working environment of special robots, the requirements for MLCCS are extremely strict. The single-machine MLCC usage can reach 5,000 to 8,000 pieces, and they need to withstand a wide temperature range of -55 ℃ to 150℃ as well as high-pressure environments.以上翻译结果来自有道神经网络翻译(YNMT)· 通用场景

Although the application of special robots is relatively single, their usage requirements are extremely high. With the continuous advancement of technology and the integration of new technologies such as multimodal perception fusion and autonomous navigation, the overall performance of global special robots has been continuously improving, enabling them to better adapt to complex environments and task requirements.

The technical differentiation of robot MLCC selection based on application scenarios

The usage specifications of MLCC also vary among different types of robots.

PART.01

Industrial robotic arm

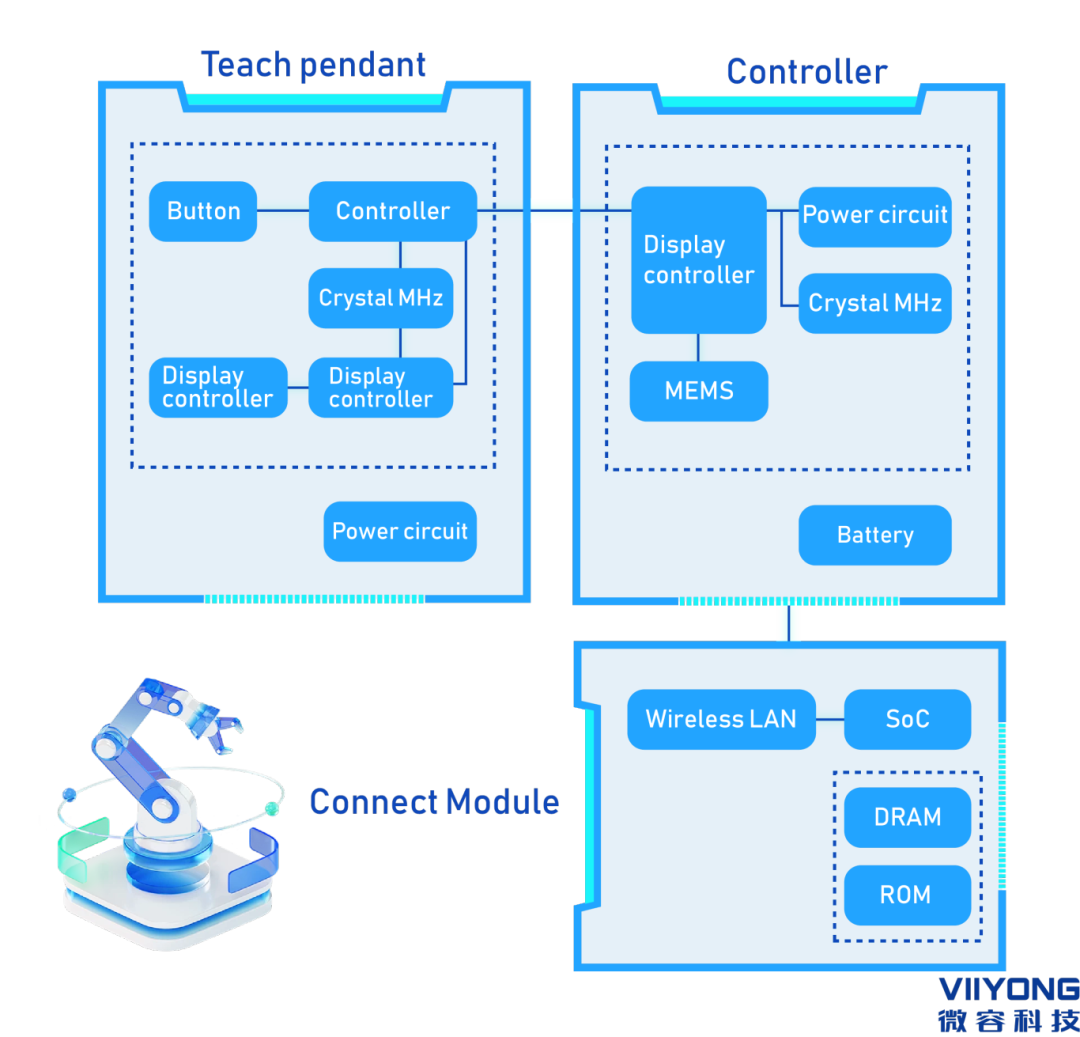

The main structure consists of three units: the Teach pendant, the Controller and the Connect module.

Among them, typical application specifications include:

0402/X7R/100nF/50V: Suitable for high-frequency filtering scenarios in servo drive circuits, the X7R medium combines the advantages of temperature stability and capacity density.

0402/X5R/1μF/10V: It is often used for energy storage filtering in control modules. The 1μF capacity value meets the transient energy compensation requirements of medium and small power signal chains.

0402/X5R/10μF/10V: Applied in low-voltage signal processing units, the 10μF capacity rating meets the energy storage optimization design requirements of long-endurance systems.

PART.02

AGV mobile robot

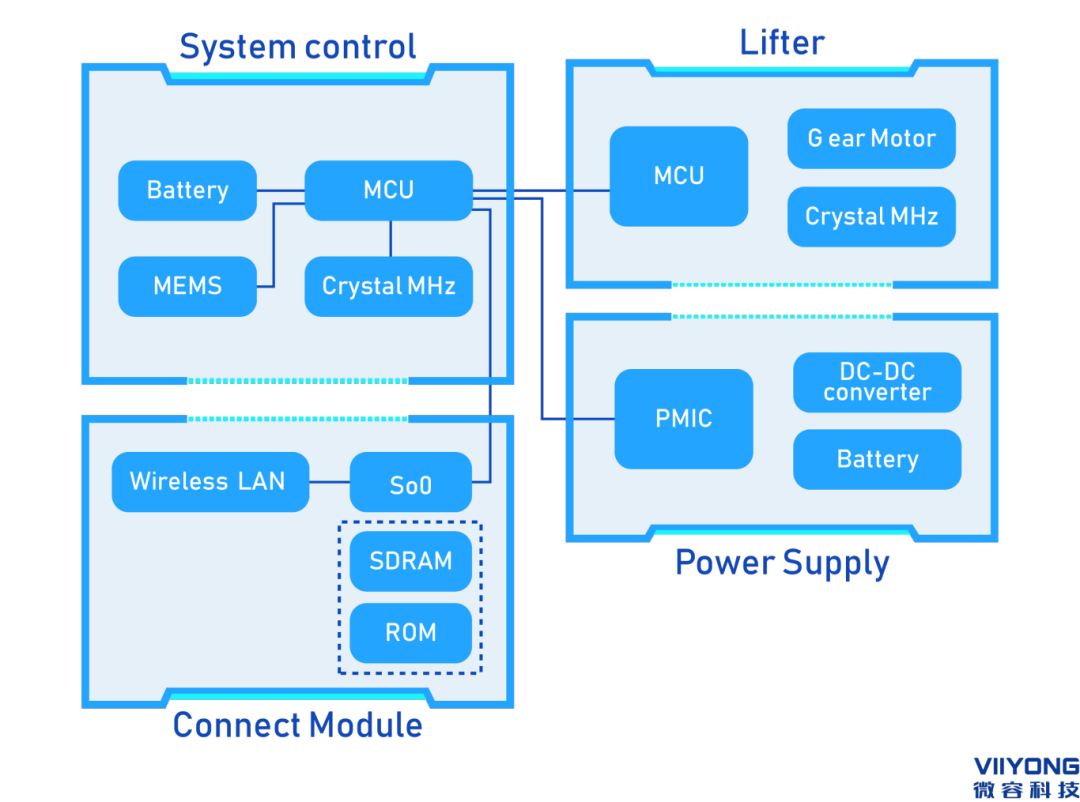

The main structure is composed of four major units: System Control, Lifter, Connect Module and Power Supply.

0402/X7R/100nF/50V: It is responsible for high-frequency noise suppression in the battery management system, and the 50V withstand voltage is compatible with the voltage platform of multi-string lithium battery packs.

0402/X5R/1μF/16V: It is used for power filtering in navigation modules. The 16V withstand voltage design meets the surge protection requirements of vehicle power systems.

0805/X5R/2.2μF/10V: Used as an energy storage capacitor in the drive motor controller, with a larger package size to meet the heat dissipation requirements under high current conditions.

PART.03

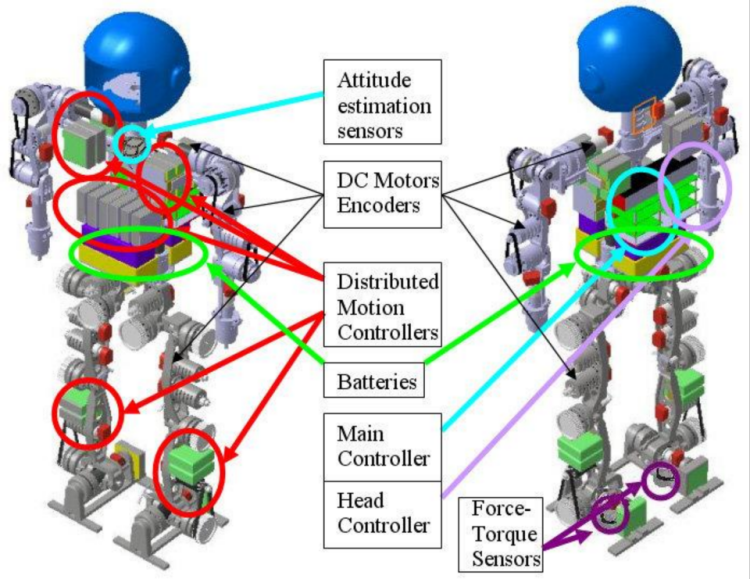

Humanoid robot

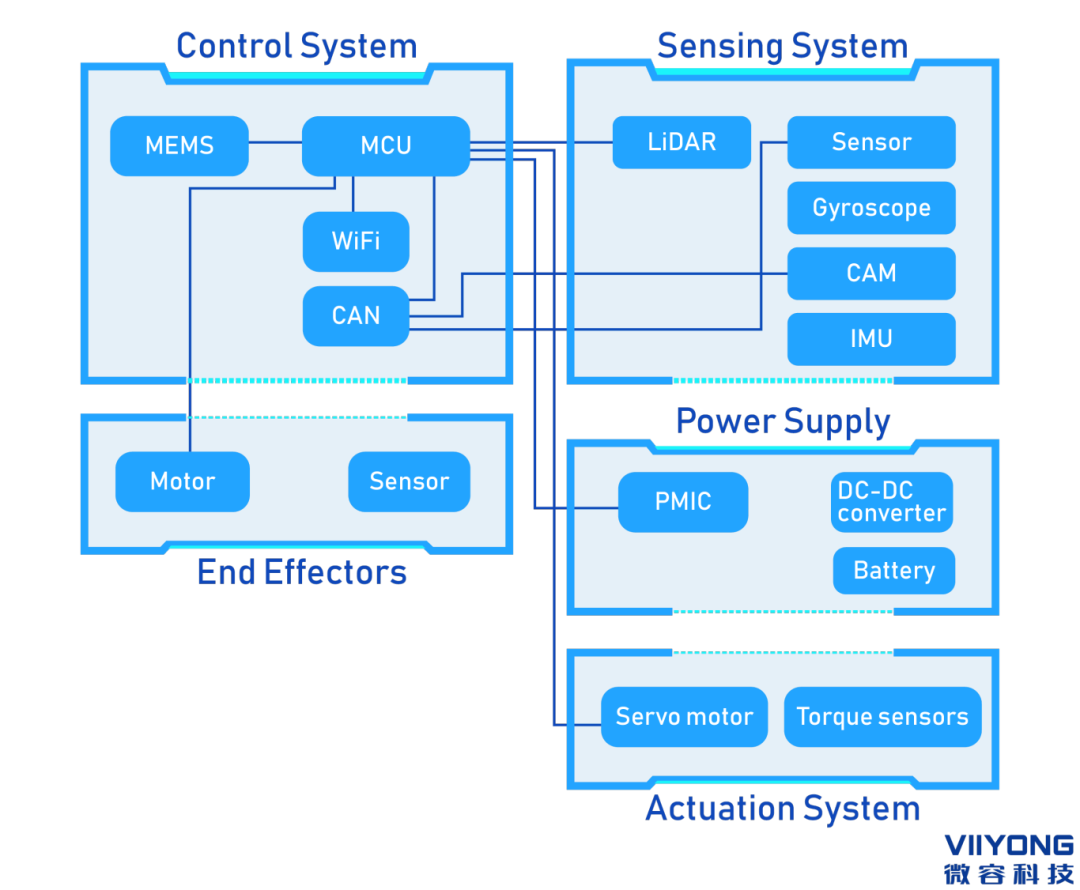

The main structure is composed of four major units: the control system, the perception system, the end effector and the drive system.

0402/X7R/100nF/50V: The universal specification is widely used in joint drive circuits, balancing capacity requirements and miniaturized design.

0805/X7R/100nF/250V: It undertakes the safety isolation function in the high-voltage servo system, and the 250V withstand voltage meets the insulation design requirements of the power unit.

1206/X5R/10μF/50V: The energy storage circuit applied to the core computing module, with a large-sized package supporting high capacitance output to cope with instantaneous power fluctuations.

The scale and trend of MLCC in the robot market

MLCC is widely used in various key parts of robots. Different parts have different requirements for its performance and specifications, which also determines its proportion and value in the cost of robots.

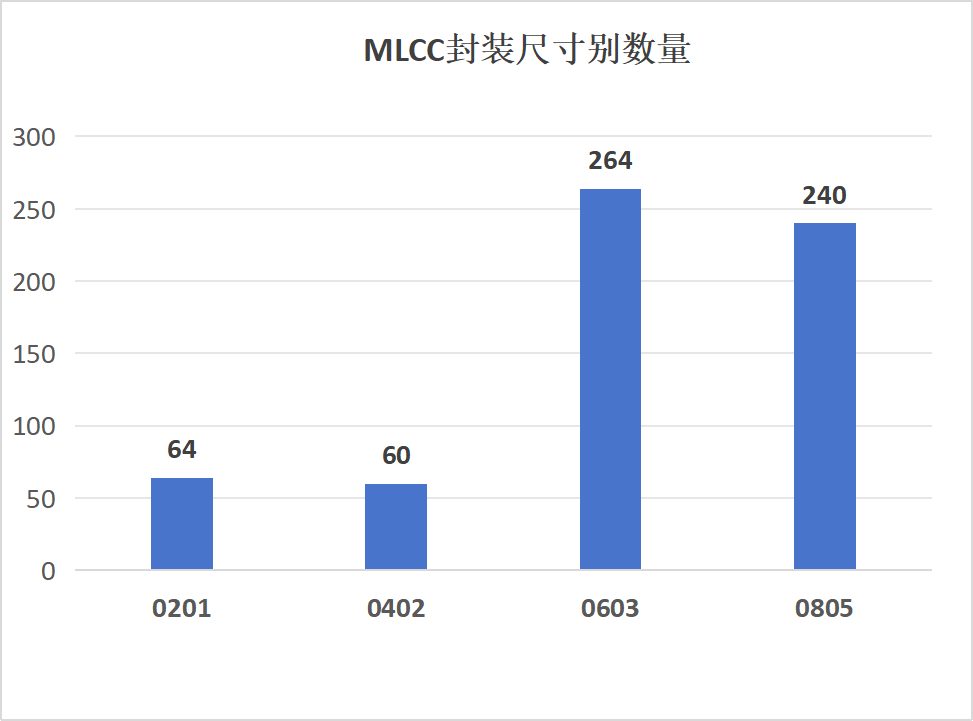

(Comparison chart of the usage of different packages)

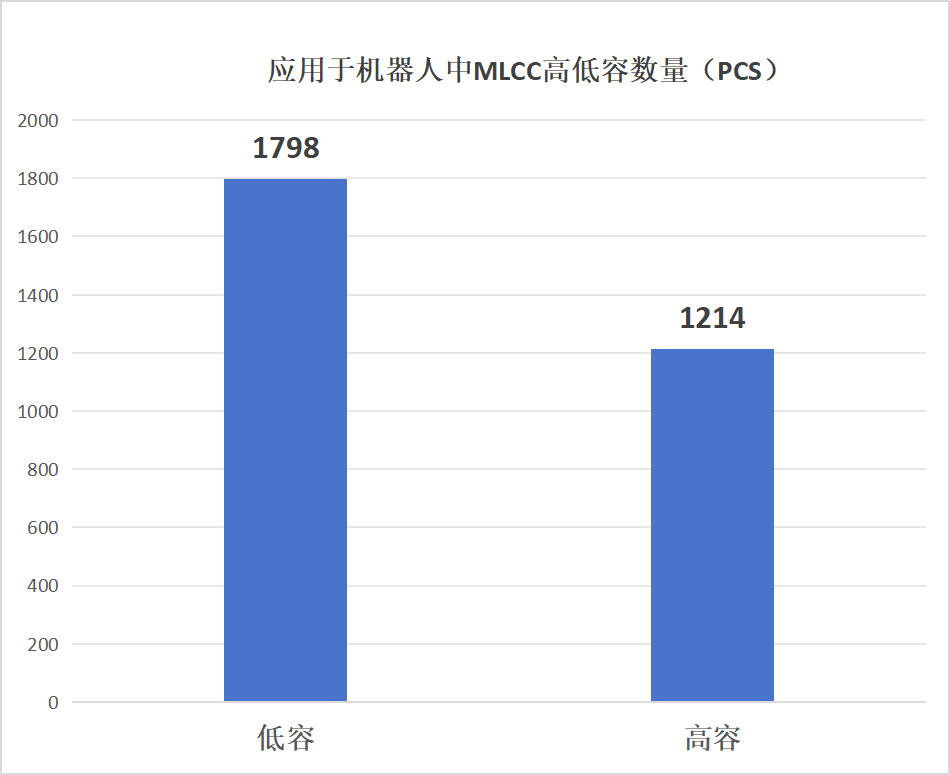

(Comparison chart of high and low capacity quantities)

Overall, the usage of MLCCS in robots shows a development trend of small size, high voltage and high capacity proportion.

Build a differentiated product matrix across multiple fields

In line with the development trend, Micro-rong Technology, with over two decades of experience in MLCC, has built a differentiated product matrix in response to the high reliability requirements of MLCC in robot application scenarios, breaking the technological monopoly of Japan and South Korea and achieving breakthroughs in multiple fields:

High-capacity series: The maximum capacity has exceeded 220μF, meeting the required conditions for MLCC in control systems.

Micro series: 0201-0402 size series are available and widely used in high-frequency filter circuits in robot systems

High-temperature resistant series: 105℃-150℃ high-temperature coverage, meeting the temperature resistance requirements of robots in cutting-edge environments.

High-voltage series: 100V-3000V voltage coverage, meeting the pulse voltage requirements of servo motors and other applications.

Automotive-grade series: Compliant with the AEC-Q200 automotive industry standard, it meets the adaptability of robots to high reliability and harsh environments, providing safety guarantees for robot systems

As a leading enterprise in the MLCC industry, Weirong Technology has focused on high-end application layout of MLCC products, precisely concentrating its corporate positioning on the independent research and development and production of high-end MLCCS. It has fully introduced advanced production and R&D equipment in the industry, and is committed to building a digital intelligent manufacturing and R&D design platform. Through technological means, it ensures that product quality meets standards.

Standing at the inflection point of technological integration, what we witness is not only the evolution of robots, but also the paradigm shift of the entire intelligent hardware industry. When every technological node is paving the way for general intelligence, the future technological landscape is no longer a solo performance of a single technology, but a symphony composed by computing power, materials and algorithms together.

| 免责声明: 本文章转自其它平台,并不代表本站观点及立场。若有侵权或异议,请联系我们删除。谢谢! Disclaimer: This article is reproduced from other platforms and does not represent the views or positions of this website. If there is any infringement or objection, please contact us to delete it. thank you! |