Products

Products

TC118AH

The TC118AH is a single-channel MOS full bridge drive with built-in power, driving forward, backward, stop and brake functions, built-in hysteresis thermal effect overheating protection function, low on-resistance (0.5Ω/1000mA).

The maximum continuous output current of the TC118AH can reach 1.8A, and the peak value is 2.5A, without the need for a large peripheral filter capacitor, only a small patch capacitor is needed.

CST6118 is recommended. CST6118 is recommended

The maximum continuous output current of the TC118AH can reach 1.8A, and the peak value is 2.5A, without the need for a large peripheral filter capacitor, only a small patch capacitor is needed.

CST6118 is recommended. CST6118 is recommended

TC118AH Description:

The TC118AH is a single-channel MOS full bridge drive with built-in power, drive forward, backward, stop and brake functions, built-in hysteresis heat effect overheat protection function, low on-resistance (0.5Ω/1000mA)

The maximum continuous output current of TC118AH can reach 1.8A, the peak value is 2.5A, there is no need for a large peripheral filter capacitor, only a small chip capacitor is needed.

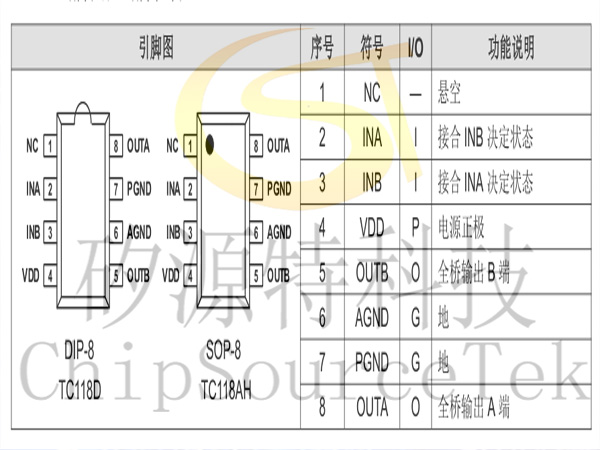

TC118AH adopts DIP-8 and SOP-8 package form.

The maximum continuous output current of TC118AH can reach 1.8A, the peak value is 2.5A, there is no need for a large peripheral filter capacitor, only a small chip capacitor is needed.

TC118AH adopts DIP-8 and SOP-8 package form.

Single channel built-in power MOS full bridge drive

Drive forward, backward, stop and brake functions

Built-in hysteretic heat effect overheat protection

Low on-resistance (0.5Ω/1000mA)

Maximum continuous output current up to 1.8A, peak 2.5A

There is no need for a large peripheral filter capacitor, only a small patch capacitor is required

Adopts DIP-8, SOP-8 package form

Drive forward, backward, stop and brake functions

Built-in hysteretic heat effect overheat protection

Low on-resistance (0.5Ω/1000mA)

Maximum continuous output current up to 1.8A, peak 2.5A

There is no need for a large peripheral filter capacitor, only a small patch capacitor is required

Adopts DIP-8, SOP-8 package form

Toy motor drive

Electronic lock

Electric toothbrush

Electric tea set

Electronic lock

Electric toothbrush

Electric tea set

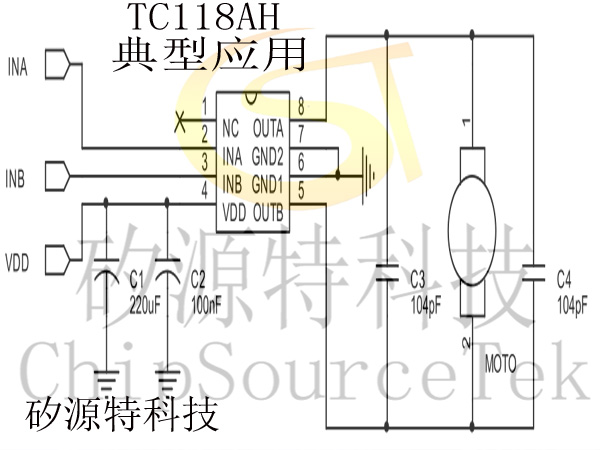

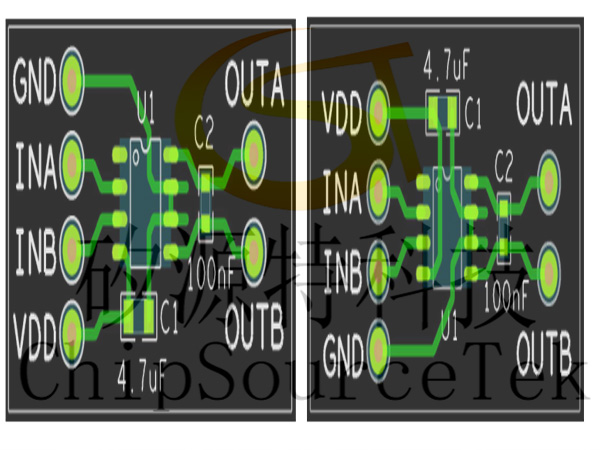

Note: In different applications, C1 and C2 can be considered only one: in 3V applications, it is recommended to use a 1uF or above; In 4.5V applications, it is recommended to use a 4.7uF or above, all using a chip capacitor; In 6V applications, it is recommended to use a large capacitor 220uF+100nF patch capacitor; C2 should be placed close to the VDD pin of the IC and the connection between the negative terminal of the capacitor and the GND terminal of the IC should be as short as possible. That is, although the capacitor is close, the wiring and wiring are wound far away (refer to the figure below). When there is a large capacitor on the application board to filter other chips and it is far away from the TC118AH, it is also necessary to place a small capacitor on the VDD foot of the TC118AH according to the above requirements. In the figure, the C4 (100nF) capacitor is preferentially connected to the motor, and when it is not convenient to weld the capacitor on the motor, it is placed on the PCB (C3).

1, the recommended circuit and parameters are only applicable to ordinary toy motor drive, other applications please use according to the actual situation.

2, continuous current drive ability is affected by packaging form, VDD voltage, chip tolerance, ambient temperature, PCB material thickness and size and other factors, specifications given parameters for reference only. In actual use, please consider a certain margin according to the product.

3, TC118AH using MOS process design and manufacturing, electrostatic sensitive, requiring in the whole process of packaging, transportation, processing and production need to pay attention to anti-static measures.

4, the motor start moment of the current value is recommended not to exceed the chip peak 2.5A.

5. When programming, it is strongly recommended to add a braking time of at least 300nS in the middle when INA switches to INB.

2, continuous current drive ability is affected by packaging form, VDD voltage, chip tolerance, ambient temperature, PCB material thickness and size and other factors, specifications given parameters for reference only. In actual use, please consider a certain margin according to the product.

3, TC118AH using MOS process design and manufacturing, electrostatic sensitive, requiring in the whole process of packaging, transportation, processing and production need to pay attention to anti-static measures.

4, the motor start moment of the current value is recommended not to exceed the chip peak 2.5A.

5. When programming, it is strongly recommended to add a braking time of at least 300nS in the middle when INA switches to INB.