1. Overview

At present, with the increasing market demand for lightweight two-wheelers, the popularity of lithium batteries in the power systems of electric two-wheelers has also further risen. The intelligent and automated control of battery systems, as well as the real-time status monitoring of battery systems, are becoming increasingly important.

The new European standard to be implemented in 2026 requires a comprehensive assessment of the power systems of electric two-wheelers from five dimensions: physical safety, environmental tolerance, scenario simulation, electrical safety and system protection. The test items include mechanical tests (such as vibration, shock, drop), environmental tests (such as condensation, temperature change), simulated vehicle accident tests (such as squeezing, immersion in water, combustion), electrical tests (such as short circuit, contact current), and system function tests (such as overcharge protection, heat dissipation failure). Through these rigorous tests, the safety and stability of the battery under various extreme conditions will be guaranteed . In addition, the new European standard also requires that the battery management system (BMS) have multiple functions, be able to read the battery status in real time, monitor the battery usage status, thereby protecting the battery system and extending the battery's service life.

Relying on its independently developed two 17-string AFE analog front-end chips, SDM91117 and SDM91217, Jinghua Microelectronics has built multiple BMS protection board solutions for electric two-wheelers and electric three-wheelers, which can meet different customer demand scenarios ranging from 10-string, 13-string, 15-string, 16-string to 17-string, covering the new industry standards such as the new European standard and the American standard.

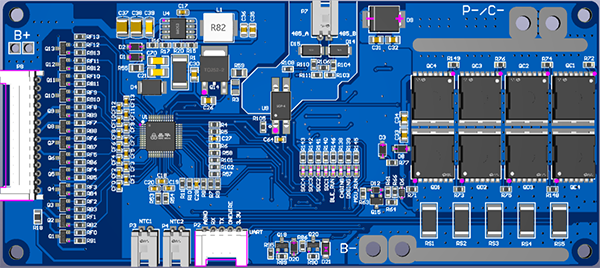

13 new European standard protection plate solutions for electric two-wheelers

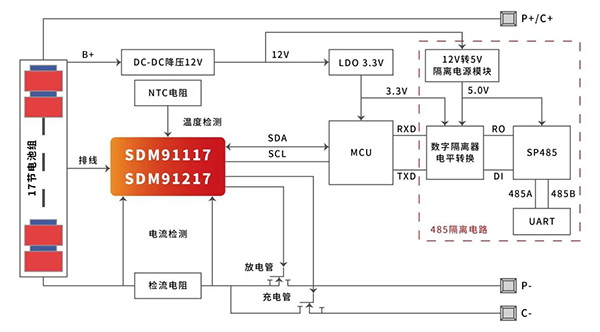

Block diagram of two-wheeler application series 10-17

As can be seen from the above figure, the BMS of electric two-wheelers mainly consists of the following parts:

1.Battery information collection, protection circuit;

2. The MCU control section includes algorithms such as SOC and SOH;

3. Charge and discharge power path;

4. Communication circuit.

2. Introduction to the Functions of the Plan

1.Battery information collection and protection circuit

This circuit includes an analog front-end AFE for individual battery collection and uses, with an integrated MOS control drive circuit inside. The AFE collects the voltage, current and temperature of the battery cells and controls the turn-off of the charging and discharging MOS in the event of overvoltage, undervoltage, undertemperature, overcurrent or short circuit, thereby achieving battery protection. The AFE integrates an internal balancing circuit, and an external balancing circuit can also be added to achieve balanced current regulation.

2. MCU control section

The MCU communicates with the analog front end AFE via I²C, obtaining information such as voltage, current, and temperature read by the analog front end. The MCU then combines the V, I, T, and other information from the analog front end with the battery charging and discharging model to calculate the SoC and SOH. Report abnormal battery information and intelligently control the AFE to achieve charge and discharge management.

3. Charging and discharging power path

The AFE integrates an NMOS low-side driver internally and can also be equipped with an external high-side driver circuit.

4. Communication sensing

To facilitate users' real-time understanding of the voltage, current, temperature and other conditions of the electric vehicle battery pack, the BMS integrates a Bluetooth /WiFi communication circuit or RS-485. Through Bluetooth /WiFi, the battery information can be synchronized to the user's mobile phone in real time.

In summary, the BMS solution for Jinghua Micro's electric two-wheelers includes information collection at the analog front end, protection circuits, MCU SoC computing, charging and discharging power paths, and optional BT/WiFi communication and RS-485 communication. This BMS solution conducts real-time monitoring of the voltage, current and temperature of individual battery packs and reports it to the user. It also performs self-control based on the protection parameters set by the user and promptly shuts off charging and discharging in case of abnormal operation of the battery pack. This solution has strong versatility. According to user requirements, within the range of 10 to 17 battery string numbers, a low-side drive same-port design scheme can be adopted. The charging and discharging current can reach up to 60-80A, and it is compatible with lithium batteries such as NCM and LFP.

3. Characteristics of the Plan

Solution features: Battery parameter detection: Detect the total voltage, current, individual cell voltage and temperature of the battery;

Battery state estimation: SoC, SOH, capacity statistics;

Fault diagnosis and alarm protection: Alarm protection for battery overvoltage and undervoltage, overtemperature and undertemperature, overcurrent and short circuit, and collected faults, etc.

Charge and discharge control and balance management: Intelligent control of battery charge and discharge, as well as charging balance.

Data storage: Parameter modification, data storage and reading at the fault site, firmware update;

Communication control: The communication methods include CAN and RS485, which can communicate with the upper computer, load equipment, charger, display device, 4G module, Bluetooth module, etc

4. Scheme Selection

SDM91217 7-17 lithium battery pack BMS front-end chip

Voltage measurement ±2mV@25℃, full temperature range less than ±10mV;

16-bit Sigma-Delta ADC, with the shortest test cycle for all voltages being 25ms;

20-bit Sigma-Delta ADC, specifically designed for current measurement, with programmable digital filtering;

Supports I²C communication up to 400kHz;

Low power consumption: 2uA in off mode, 22uA in sleep mode, 5uA in deep sleep mode, and 150uA in measurement mode;

BUS-BAR function

Built-in independent watchdog function;

Ultra-high ESD protection capability, HBM ±4kV;

It must be used in conjunction with an MCU.

SDM91117-10~ 17-cell lithium battery pack BMS front-end chip

Voltage measurement: ±5mV@25℃, less than ±15mV throughout the full temperature range;

Supports I²C communication up to 400kHz;

Low power consumption: The minimum current in the off mode is 9uA, in the sleep mode is 65uA, and in the measurement mode is 125uA.

The EEPROM can be set with first and second-level protection thresholds such as overvoltage, undervoltage, overcurrent and over-temperature.

Secondary overcharge protection function;

It is equipped with a built-in balancing switch that can provide 30mA current, and also supports the expansion of external balancing switches to achieve internal automatic parity balancing.

It can independently operate various protections without the participation of an MCU.

Configurable coulomb integration function to achieve cumulative power consumption;

It indicates the status of each string of cells and has an inbuilt watchdog function.

免责声明: 本文章转自其它平台,并不代表本站观点及立场。若有侵权或异议,请联系我们删除。谢谢! Disclaimer: This article is reproduced from other platforms and does not represent the views or positions of this website. If there is any infringement or objection, please contact us to delete it. thank you! |