With the rapid development of generative AI, smart (AI) glasses are moving from science fiction to reality and becoming powerful assistants in people's lives. According to the Wellsenn XR data report [1], the global sales volume of AI glasses was 1.52 million units in 2024 and is expected to surge to 3.5 million units in 2025, representing a year-on-year growth of 130%.

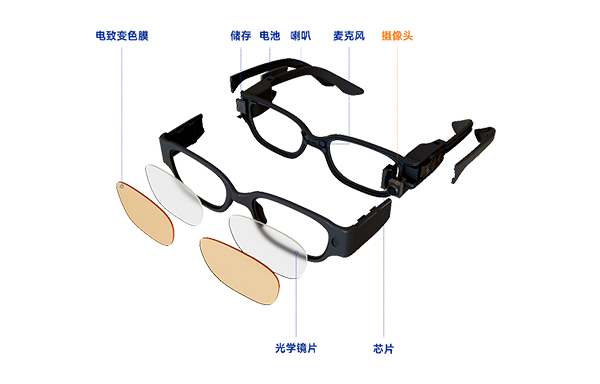

Behind this excitement, a technological challenge is unfolding. CMOS image sensors (CIS) are the eyes of AI glasses and are being given more and more room for imagination. However, CIS must play a game between "small" and "powerful". How can one accommodate more powerful imaging capabilities within a narrow frame of less than 1cm ² and a weight of less than 40 grams under the red line? This is precisely the technical proposition that the industry must confront directly.

The high-performance CIS packaging technology of Goke Innovation - TCOM (Tiny Chip On Module) packaging was precisely developed for this purpose.

小型化:TCOM封装技术的突破

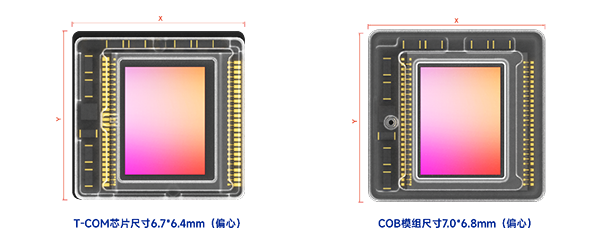

TCOM是基于格科高性能COM封装技术升级而来,专为空间敏感应用研发。COM封装技术可媲美高端COB(Chip On Board)封装,具备更优异的光学系统性能和背压可靠性等。在长期的量产实践中,受到客户高度认可,目前累计出货总量超过5亿颗。

在此基础上,TCOM升级结构与工艺,在有限空间内构建高性能影像模组。相比同规格COB封装芯片,模组尺寸缩小10%。而且,与行业现行的小型化方案相比,具备显著的成本优势和更高的背压可靠性。

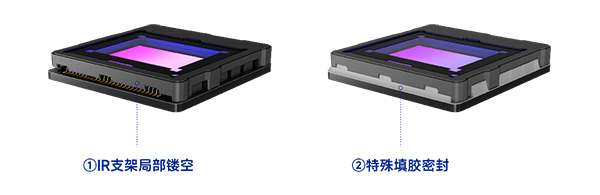

How did Goke achieve this breakthrough design?

The current miniaturized CIS packaging solution is confronted with the dual challenges of cost and back pressure reliability. This solution is based on the COB structure and uses special Molding molds and equipment to seal the molds of components, chips, circuit boards, etc. Although the module size can be reduced and the structural strength is high, the resulting cost is relatively high. Meanwhile, as CIS is directly mounted on the circuit board, it is more sensitive to

Illustration of the TCOM process steps

Through the above unique design, the TCOM module not only shortens the length and width but also does not sacrifice structural strength. It can be adapted to the compact design of AI glasses where "the frame is the lens", reserving more space for the layout of other components in the device and making "all-weather seamless wearing" possible.

From AI glasses to mobile phones, expand more possibilities

The application scenarios of TCOM technology are far more than just AI glasses. Smartphones, tablets and other terminals are in fierce competition, and TCOM packaging technology has brought new possibilities.

Take mobile phones as an example. TCOM can further reduce the size of the front camera module, making the position of the front camera more flexible and allowing it to be designed close to the screen border, thus bringing a better full-screen effect. For the rear camera, TCOM can increase the module height, reduce the protrusion of the camera module, make the phone thinner, and further enhance the overall competitiveness of the device.

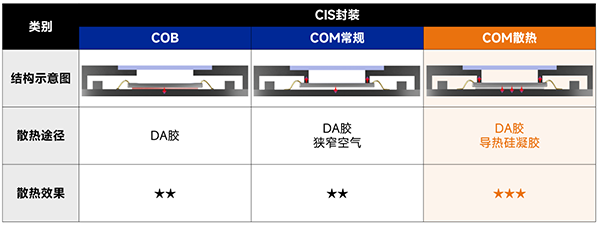

The more compact the space is, the more crucial heat dissipation becomes. In response to this challenge, Goke has developed a COM solution with heat dissipation advantages.

When a mobile phone continuously shoots high-resolution and high frame rate images, it often gets hot easily. If the heat dissipation is poor, it will affect the stability and safety of the equipment. The statistical results show [2] that for every 10℃ increase in the temperature of the electronic components inside the mobile phone, its reliability will decrease by 50%. It is worth noting that among all the factors that cause electronic device failures, faults caused by high temperatures account for as high as 55%.

The COM heat dissipation solution adds highly efficient thermal conductive silicone gel to the traditional DA glue heat dissipation material, further enhancing the heat dissipation effect. Actual measurement data shows that based on a 50MP 1.0μm CIS module in 4K 60fps mode, the COM package can reduce the module temperature by approximately 5°C compared to COB, which is equivalent to having an external cooling fan when using a mobile phone!

Perhaps in the near future, when we put on that pair of "imperceptible existence" smart glasses, what we will see is not only a world where the virtual and the real blend, but also a future where technology and user experience resonate - smart enough and light enough.

At present, Goke's 5-megapixel CIS has been mass-produced in the AI glasses project. In the future, Goke will continue to take CIS as the core and combine it with high-performance CIS packaging solutions such as the COM series to equip devices with thinner, lighter and smarter "eyes".

免责声明: 本文章转自其它平台,并不代表本站观点及立场。若有侵权或异议,请联系我们删除。谢谢! Disclaimer: This article is reproduced from other platforms and does not represent the views or positions of this website. If there is any infringement or objection, please contact us to delete it. thank you! |