More and more motors have been applied to automobiles. Choosing a brushed DC motor drive that meets the automotive grade requirements can simplify the design and improve safety performance. This article introduces to you the function-enhanced H-bridge pre-drive chip HCV7535 that meets the requirements of automotive grades. The application of motors in automobiles enables cars to be automated, enhancing driving safety and comfort. Different types of motors are applied to various functional modules of automobiles due to their own characteristics. Brushed DC motors are also used in multiple functional modules of automobiles, as shown in the following figure. Automatic window regulators are now available in almost every car, eliminating the need for the traditional hand-craned ones. Electric seat adjustment has also replaced the traditional manual mechanical type. The electric trunk and electric sunroof are even more common in luxury cars, all of which are achieved through brushed DC motors. To drive a brushed DC motor, either high-side drive or low-side drive can be used. Just connect the control power supply to the motor's ground input terminal, which is simple and practical. When it is necessary to control the motor to achieve forward and reverse rotation, an H-bridge can be built to achieve this, as shown in the H-bridge drive in the following figure.

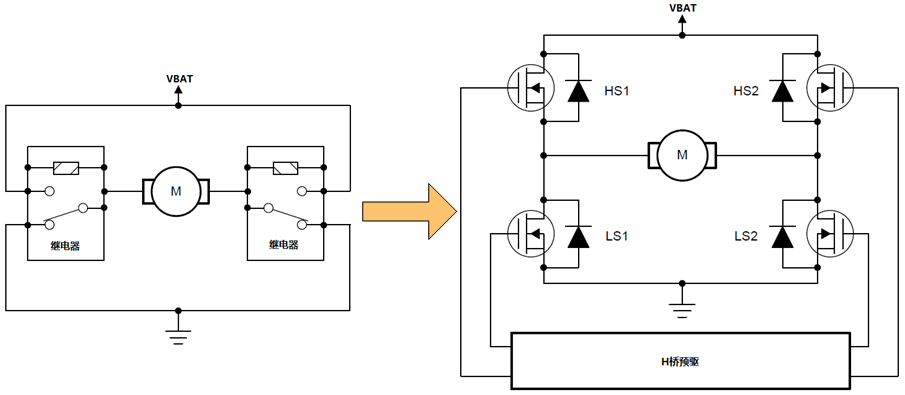

A simple H-bridge circuit can be achieved by using two relays, and the external circuit can drive the relays to close. Although such a relay H-bridge drive is simple and practical, it also has relatively significant limitations, such as a large volume and slow switching speed. Moreover, it is also inadequate in terms of speed regulation. Under the current trend of high power density demand, it is necessary to use devices with higher switching speeds and smaller volumes to replace relays. Mosfet switches are fast, have low on-resistance, strong overcurrent capacity, and are non-contact electronic switches. They are very suitable for replacing relays to drive brushed DC motors and are also easier to reduce the space occupied by circuits. Because the switching speed of MOSFETs is very high compared to that of relays, speed regulation can be achieved through PWM. The requirements for automotive electronic design are getting higher and higher. Functional safety and fault detection mechanisms are indispensable parts. Design the drive of DC brushed motors that meet automotive standards.

A brushed DC motor is a type of DC motor. On the stator of a brushed motor, there are fixed main poles and brushes, and on the rotor, there are armature windings and commutators. The electrical energy of the DC power supply enters the armature winding through the brushes and commutator, generating armature current. The magnetic field produced by the armature current interacts with the main magnetic field to generate electromagnetic torque, causing the motor to rotate and drive the load. Due to the presence of brushes and commutators, brushed motors have a complex structure, poor reliability, frequent faults, large maintenance workload, short service life, and commutation sparks are prone to cause electromagnetic interference. In modern automotive electronic systems, brushed DC motors are widely used in electric seat adjustment mechanisms, achieving multi-level position memory functions through PWM speed regulation technology. In the vehicle air conditioning system, the damper actuator driven by this motor can precisely control the direction and flow rate of the air outlet. The electric power steering system adopts a high-torque brushed DC motor to provide precise directional control torque. The household drum washing machine adopts a brushed DC motor as the drive core. Its smooth start-up characteristic effectively reduces vibration and noise. Among vacuum cleaner products, high-speed brushed DC motors can generate a powerful suction force of over 20kPa. The inverter refrigerator compressor adopts a specially designed brushed DC motor, achieving energy-saving performance with an energy efficiency grade of A++.

In the flap control system of civil airliners, the redundantly designed brushed DC motor units ensure the absolute reliability of flight attitude adjustment. The stabilization mechanism of the drone gimbal adopts a micro brushed DC motor to achieve anti-shake compensation for the captured images. The solar panel deployment mechanism of the spacecraft relies on space-grade brushed DC motors to achieve precise Angle positioning. The impact drill adopts a high-power-density brushed DC motor and can maintain a stable rotational speed even at a rated power of 600W. The Angle grinder is equipped with an industrial-grade brushed DC motor and can operate continuously for 4 hours without overheating protection. The waterproof brushed DC motor used in the garden chainsaw can maintain a cutting speed of 3000rpm in a humid environment. From the above application examples, it can be seen that brushed DC motors, with their mature technical processes and good cost-performance advantages, continue to play a key role in many industrial fields, demonstrating strong technological vitality.

Introduction to Brushed DC Motors: Brushed DC motors, also known as brushed motors, are a type of DC motor widely used in household appliances. Its key components include the fixed main poles and brushes on the stator, as well as the armature windings and commutator on the rotor. In daily life and numerous electronic products, brushed micro DC motors play a crucial role. These motors are widely used in household small appliances, providing power for various products such as coffee machines, razors, facial cleansers and beauty devices, etc. In daily life, brushed micro DC motors are often used in household small appliances, such as coffee machines, razors, facial cleansers and beauty devices. The operation of these devices all relies on the power provided by brushed micro DC motors.

Brushed micro DC motors have won wide applications due to their simple control methods and low costs. This type of motor can operate simply by being supplied with direct current and can be easily controlled by adjusting the voltage. In contrast, brushless micro DC motors require additional circuit support and have relatively small torque at low speeds. Products with torque requirements also need to add a reducer. In addition, brushless micro DC motors also have relatively high requirements for product design structure and cost. Therefore, in most cases, brushed micro DC motors have become the preferred choice for electronic products. Unless the product has extremely high requirements for parameters and cannot be achieved through brushed motors, brushless DC motors will be considered.

免责声明: 本文章转自其它平台,并不代表本站观点及立场。若有侵权或异议,请联系我们删除。谢谢! Disclaimer: This article is reproduced from other platforms and does not represent the views or positions of this website. If there is any infringement or objection, please contact us to delete it. thank you! |