Author: Prasad Paruchuri, Technical Marketing Department, ON Semiconductor

With the continuous advancement of technology, we are now able to develop batteries that are more compact, have greater power, longer service life and faster charging speed than ever before.

On the roads, the number of battery-powered vehicles is increasing day by day. In the home, all kinds of devices, from handheld power tools to lawn mowers, have been made wireless. In the field of construction, equipment such as hammer drills, impact wrenches, circular saws, and nail guns all rely on battery power. In the warehouse, material handling equipment such as forklifts, pallet trucks, and automated guided vehicles (AGVs) have all benefited significantly from the improvement in battery performance.

As battery-powered devices become increasingly popular, fast charging is crucial for enhancing the convenience of such devices. This article discusses the standards that must be considered when designing an efficient battery charging system, introduces the commonly used topologies, and elaborates on how onsemi's power semiconductors can help achieve high-performance solutions.

Battery charging system

The battery charging system is applicable to various types of chemical batteries, including lead-acid batteries, nickel-metal-hydride batteries and lithium-ion batteries. At present, most battery-powered devices use lithium-ion or lithium phosphate batteries ranging from 12V to 120V. Battery chargers must be designed according to the requirements of the application and the working environment. For handheld power tools, the battery charger must be compact and lightweight, and be capable of operating without forced heat dissipation. Such small and efficient chargers require high energy density, which demands that the chargers must have low power loss and smaller heat sinks, while fast charging requires high-frequency chargers.

In industrial applications, chargers must be robust and durable, capable of withstanding harsh indoor and outdoor environments, and may need to be powered by an AC power supply of 120-277V or even 480V.

Therefore, designers must carefully select the best topology for their final application and optimize device selection to meet the requirements of cost performance.

Battery charging topology

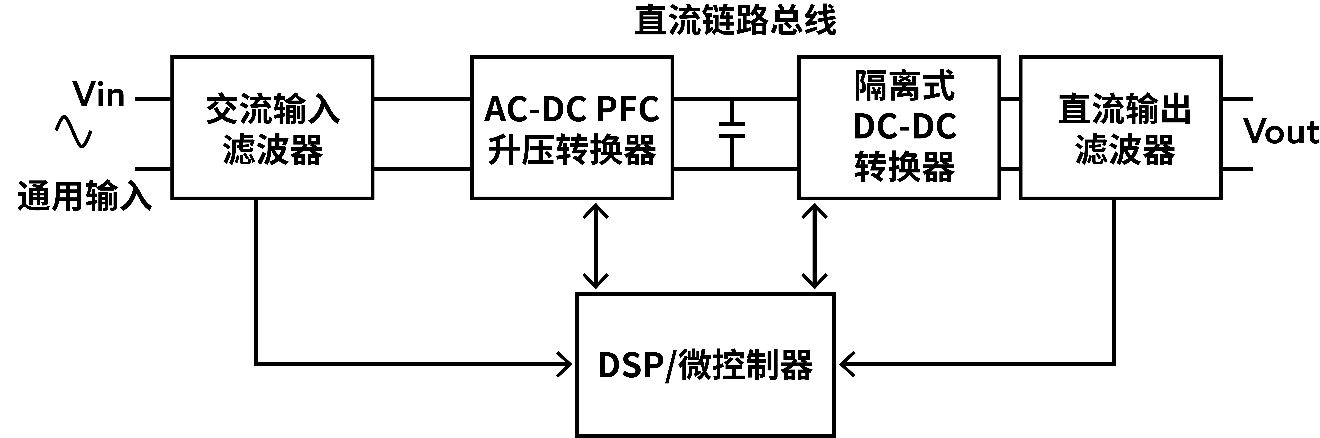

Figure 1 shows the block diagram of a typical battery charging system. At the front end, the input voltage from the mains power is filtered and then converted into DC voltage through the power factor correction (PFC) circuit. The second stage of this system consists of DC-DC conversion and constant voltage/constant current control functions, which are used to provide the required charging output.

Select the best topology for the application

Next, we will analyze several circuit topologies and discuss their applicability in different battery-powered applications.

1、PFC Topology

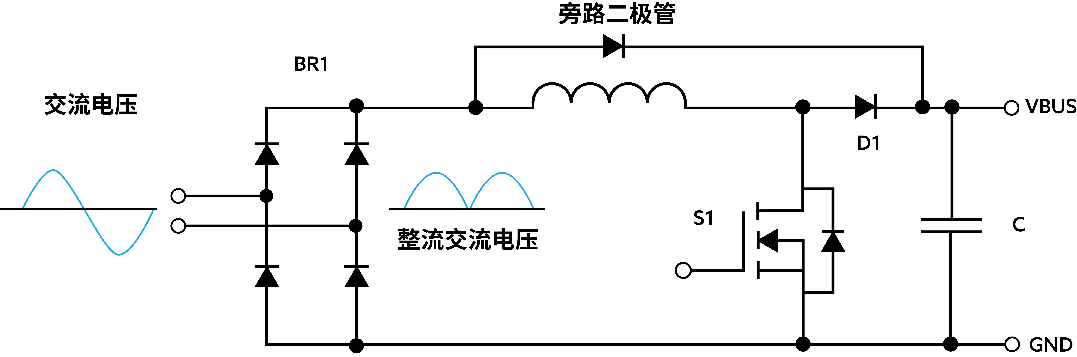

The continuous conduction mode boost topology (Figure 2) is the simplest and lowest-cost PFC topology, which consists of an input EMI filter, a bridge rectifier, a boost inductor, a boost FET and a boost diode.

For higher-power applications, ON Semiconductor's FAN9672 and FAN9673 PFC controllers are good choices. Silicon carbide (SiC) has significant advantages in charging applications, including low switching losses and high operating frequencies. Therefore, it is recommended to use SiC boost diodes in PFC design. In high-power applications ranging from 2KW to 6.6KW, the losses of the input bridge are significantly higher. These losses can be reduced by replacing diodes with active switches such as Si MOSFETs or SiC MOSFETs.

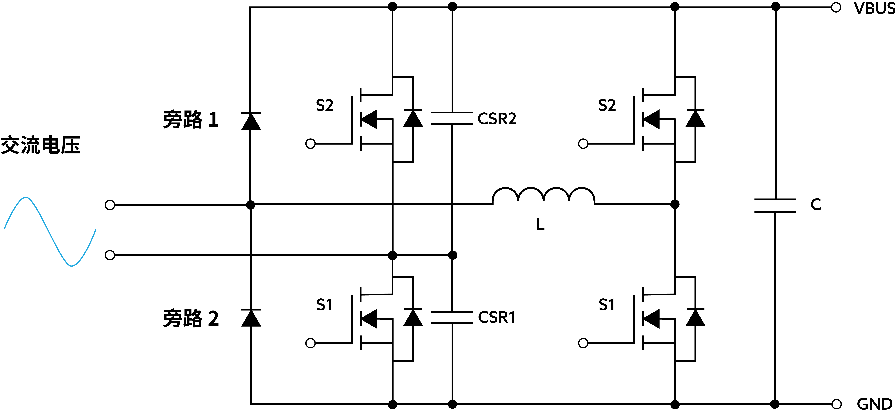

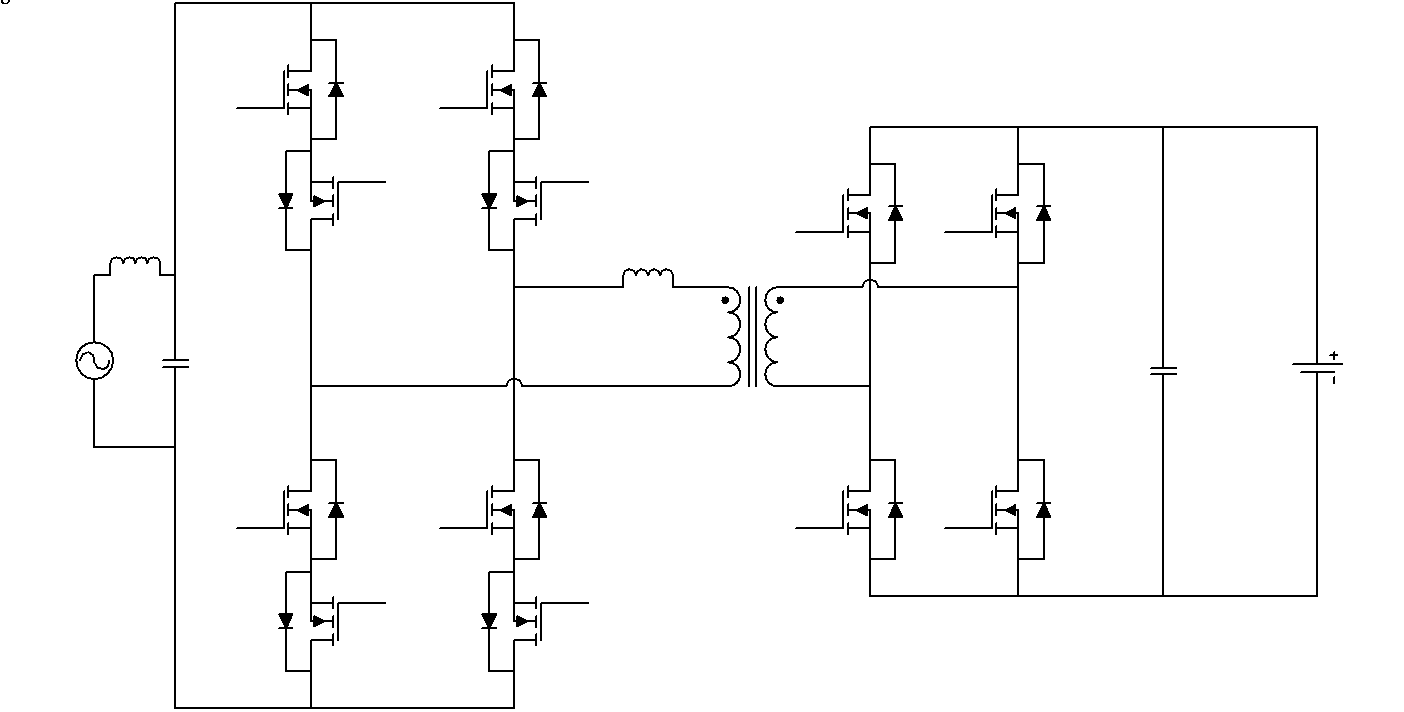

Other common topologies include semi-bridge-free PFC and totem pole PFC (TPFC), which eliminate bridge rectifiers and have lower losses. The TPFC (Figure 3) is composed of an EMI filter, a boost inductor, a high-frequency half-bridge, a low-frequency half-bridge, a dual-channel gate driver and a fixed-frequency TPFC controller.

On Semiconductor's 650V EliteSiC MOSFET offers a range of options for high-frequency bridge arms designed for TPFC. For 3.0kW applications, the NTH4L032N65M3S can be considered. For applications up to 6.6kW, the NTH4L015N65M2 and NTH4L023N065M3S are good choices. For the low-frequency bridge arm of the TPFC circuit, the NTHL017N60S5 device is a suitable choice.

2、Isolated DC-DC converter

For isolated DC-DC conversion, a variety of different topologies can be adopted depending on the power level of the application.

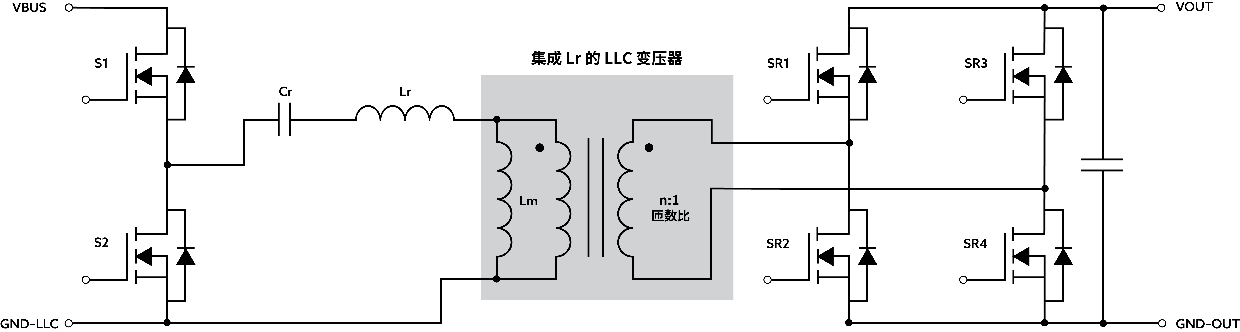

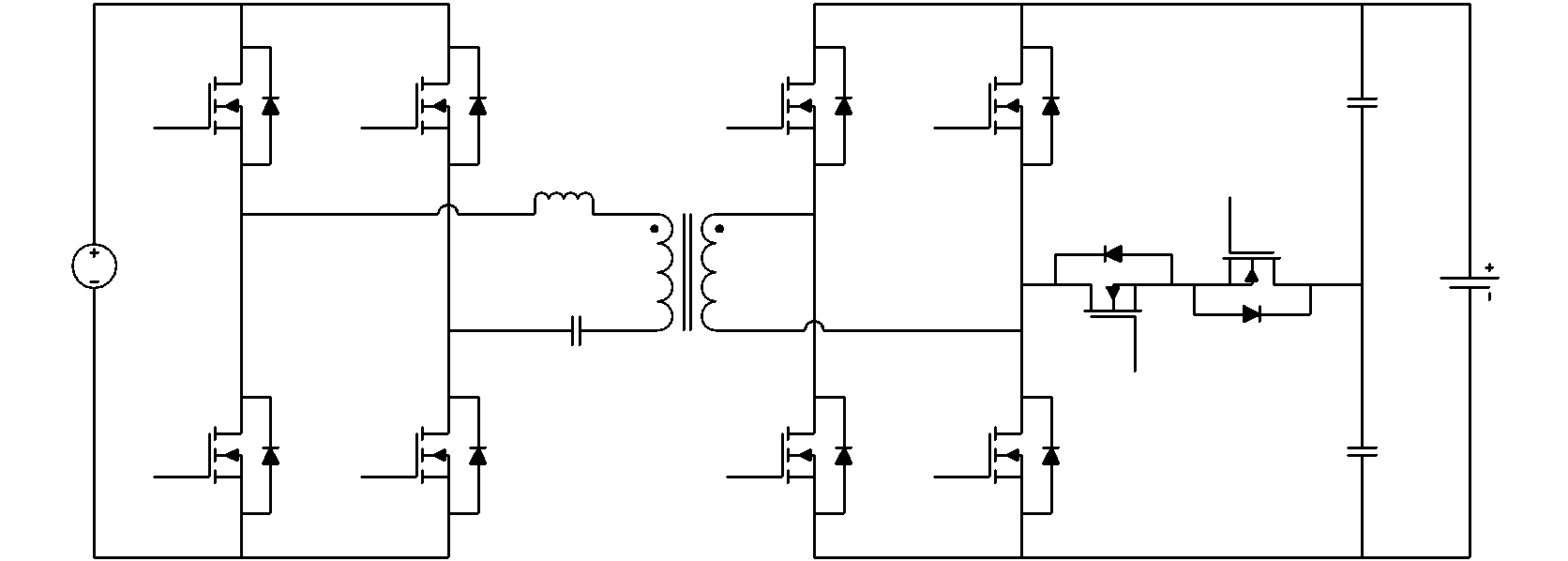

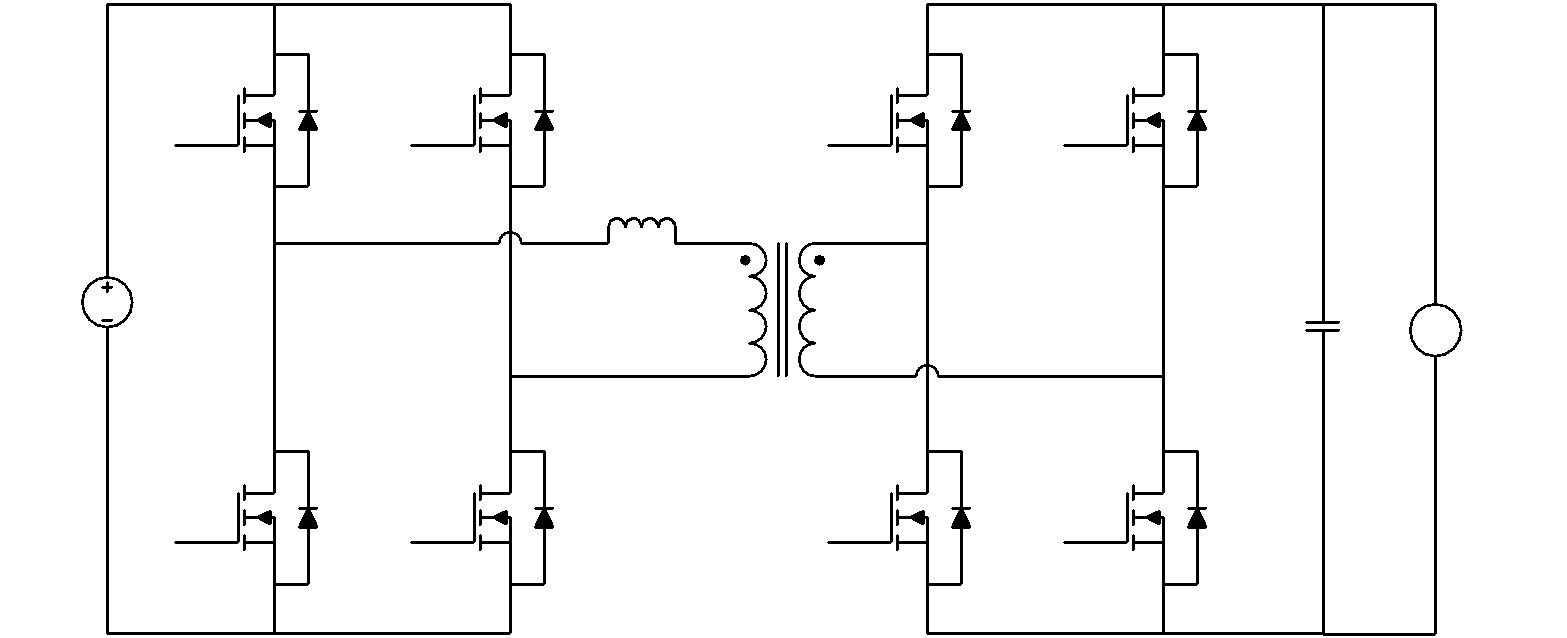

The half-bridge LLC topology with a secondary side-synchronous bridge rectifier (Figure 4) is highly suitable for charger applications ranging from 600W to 3.0KW. Depending on the power level, GAN power switches (NCP58921, 600W to 1.0KW) or SiC MOSFETs (2KW and 3.0KW) can be used. For applications with higher power levels (4.0KW to 6.6KW), designers should consider adopting full-bridge LLC (Figure 5) or staggered LLC topologies.

Optimize topology and device selection

The convenience of power tools and equipment depends on whether the battery can be charged quickly and efficiently. Designers of battery charging solutions must consider the required power level and operating voltage and carefully select the best topology. In addition, the devices selected by the designers for the design must be able to meet the performance requirements of the application.

On Semiconductor's product portfolio covers a wide range of low-voltage, medium-voltage and high-voltage power discrete devices, including silicon-based devices such as diodes, MOSFETs and IGBTs. Switching devices based on SiC are increasingly favored because they feature faster switching speeds and excellent low-loss operating characteristics, thus enabling the improvement of power density without sacrificing performance. With ON Semiconductor's chip and packaging technologies, ON Semiconductor's power devices feature outstanding quality and robustness, enabling you to exceed your design goals.

| Disclaimer: This article is reproduced from other platforms and does not represent the views or positions of this website. If there is any infringement or objection, please contact us to delete it. thank you! 矽源特科技ChipSourceTek |