In the Field of modern motor Control, field-oriented control (FOC) has become the core technology of driving AC motors with its efficient and accurate characteristics. Whether it is an industrial robot or a household appliance, FOC splits the stator current into torque and excitation components by simulating the control mode of a DC motor, significantly improving dynamic response and energy efficiency. FOC is classified into inductive FOC and non-inductive FOC according to whether it relies on physical sensors. Each FOC has its advantages and disadvantages and is suitable for different scenarios. This paper will deeply analyze its principle, characteristics and application.

The core idea of FOC is to convert the stator current of a three-phase AC motor into the direct axis (Id, excitation component) and the alternating axis (Iq, torque component) in a rotating coordinate system through coordinate transformation (Clarke/Park transformation). In this coordinate system, Id and Iq control it independently, just as they control a DC motor, thus achieving precise control of the speed, position and torque of the motor.

Inductive FOC algorithms usually require the use of magnetic sensors (such as Hall sensors), optical encoders, or magnetic encoders to accurately sense the position and speed of the motor rotor. The working principle is based on the magnetic field oriented control theory, the real-time position information of the rotor is obtained by the sensor, and the three-phase current and voltage of the motor are transformed to the rotating coordinate system (dq axis) which is oriented by the rotor magnetic field. The advantages of the algorithm are high control accuracy and good stability, and it can achieve accurate positioning and speed control of the motor under various working conditions. It is suitable for occasions with high control accuracy and dynamic performance requirements, such as industrial robots, CNC machine tools, aerospace and other fields. However, the disadvantage is that additional sensors need to be installed, which increases the cost, complexity and volume of the system, and the installation and maintenance of the sensor also requires certain technology and costs.

However, the sensors and interface circuits in the inductive FOC increase hardware costs and take up installation space. At the same time, the sensor is easy to fail in harsh environments such as vibration and oil pollution.

The non-inductive FOC algorithm does not need to use a special position sensor to detect the rotor position, but by detecting the phase current, back electromotive force or other electrical gas of the motor, using a complex algorithm to estimate the position and speed of the motor rotor. The common methods are based on back electromotive force method, stator flux method, inductance method, etc., and some use the combination of position observer and inverse tangent or phase locked loop (PLL) calculation to form the position observation algorithm.

The non-inductive FOC algorithm also coordinates the current and voltage of the motor and controls it in the dq axis coordinate system, but the position and speed of the rotor are obtained through the calculation and analysis of the sampled data. The advantage of this algorithm is to reduce the system cost, improve the reliability and anti-interference, reduce the motor volume and complexity, suitable for cost-sensitive, limited installation space and control accuracy requirements are not very high occasions, such as household appliances, power tools, industrial fans, etc. However, the disadvantage of the non-inductive FOC algorithm is that at low speeds, due to the smaller back electromotive force, the difficulty of signal detection and processing, the estimation accuracy is reduced, the control performance is not as good as that of the inductive FOC algorithm, and the algorithm complexity is high, which has certain requirements on the computing power of the controller.

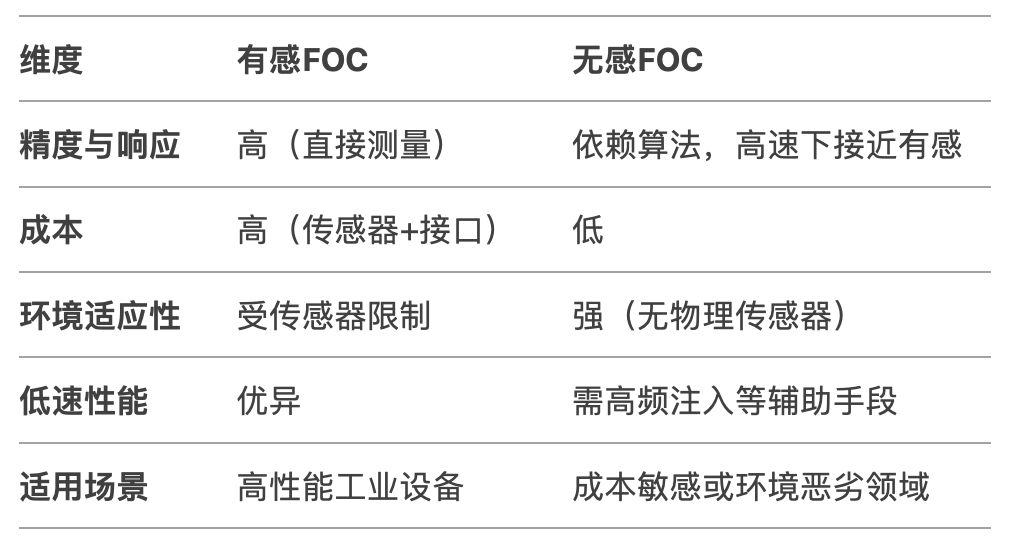

To sum up, the pair between inductive FOC and non-inductive FOC is shown in the figure below.

Facing the future, with the improvement of chip computing power and the evolution of intelligent algorithms, non-inductive FOC is gradually penetrating into high-end fields. For example, in the redundant drive system of new energy vehicles, the non-inductive scheme can be used as backup control; The integration of AI parameter self-tuning technology further improves the adaptability of non-inductive FOC. However, in scenarios where absolute accuracy and reliability are required (e.g., aerospace, servo), inductive FOC is still preferred.

免责声明: 本文章转自其它平台,并不代表本站观点及立场。若有侵权或异议,请联系我们删除。谢谢! Disclaimer: This article is reproduced from other platforms and does not represent the views or positions of this website. If there is any infringement or objection, please contact us to delete it. thank you! |