Electromagnetic interference (EMI) in design has always been a headache, especially in the automotive sector. In order to minimize electromagnetic interference as much as possible, designers often reduce the noise source by reducing the loop area of high di/dt and the switching rate when designing the schematic and drawing the layout.

However, sometimes no matter how carefully the layout and schematics are designed, it is still not possible to reduce conducted EMI to the desired level. This is because the noise depends not only on the parasitic parameters of the circuit, but also on the current intensity. In addition, the action of switching on and off creates discontinuous currents that create voltage ripples across the input capacitor, increasing EMI.

Therefore, it is necessary to adopt some other methods to improve the performance of conducted EMI. This paper mainly discusses the introduction of input filter to filter out the noise, or increase the shield to lock the noise.

Figure 1 Schematic diagram of EMI filter

Figure 1 shows a simplified EMI filter, including a common mode (CM) filter and a differential mode (DM) filter. Generally, DM filters are mainly used to filter noise less than 30MHz (DM noise), and CM filters are mainly used to filter noise from 30MHz to 100MHz (CM noise). But in fact, these two filters have a certain suppression effect on the EMI noise of the entire frequency band.

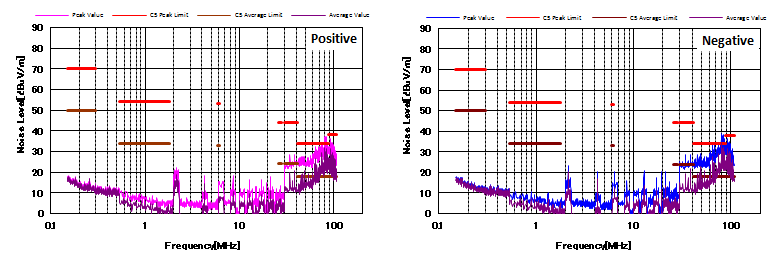

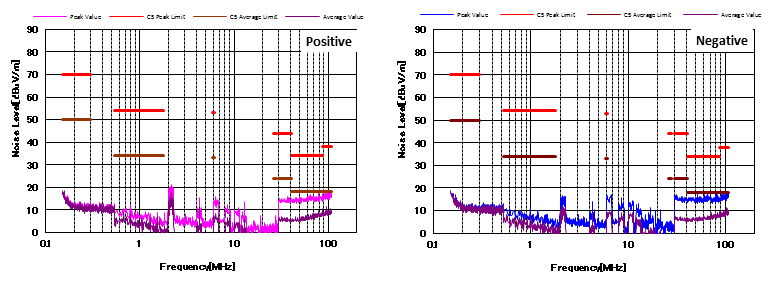

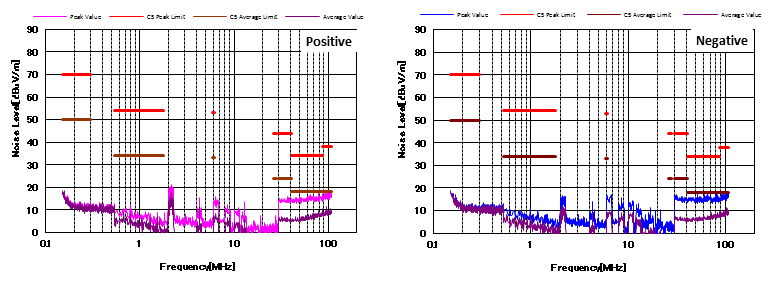

Figure 2 shows an input lead noise without filter, including positive and negative noise, and labels the peak and average levels of these noises. Among them, the system under test mainly uses chip LMR14050SSQDDARQ1 to output 5V/5A, and supplies power to subsequent chips TPS65263QRHBRQ1, while output 1.5V/3A, 3.3V/2A and 1.8V/2A. Both chips operate at a switching frequency of 2.2MHz. Additionally, the conducted EMI standard shown in the figure is CISPR25 Class 5 (C5). For more information about the system, see Application Note SNVA810.

Figure 2 Noise characteristics under C5 standard (without filter)

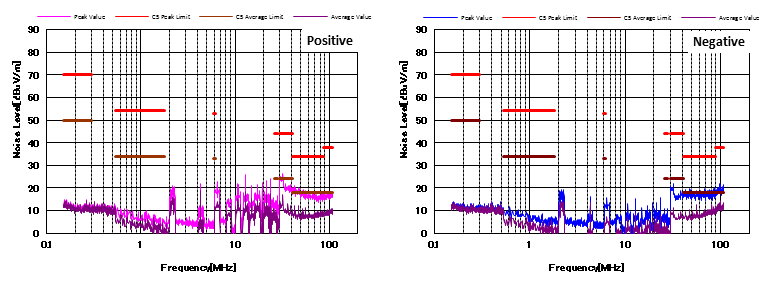

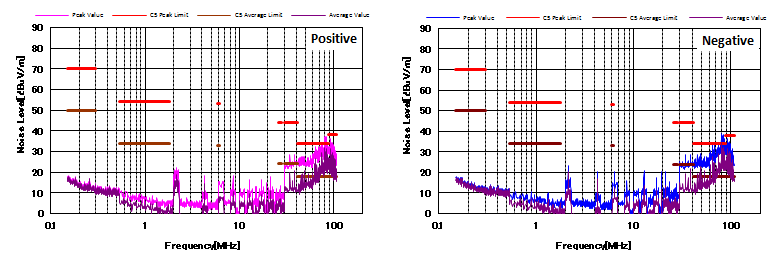

Figure 3 shows the EMI result after adding a DM filter. As can be seen from the figure, the DM filter attenuates mid-band DM noise (2MHz to 30MHz) by nearly 35dBμV/ m. In addition, high-band noise (30MHz to 100MHz) has also been reduced, but still exceeds the limit. This is mainly due to the limited ability of DM filters to remove high frequency CM noise.

Figure 3 Noise characteristics under C5 standard (with DM filter)

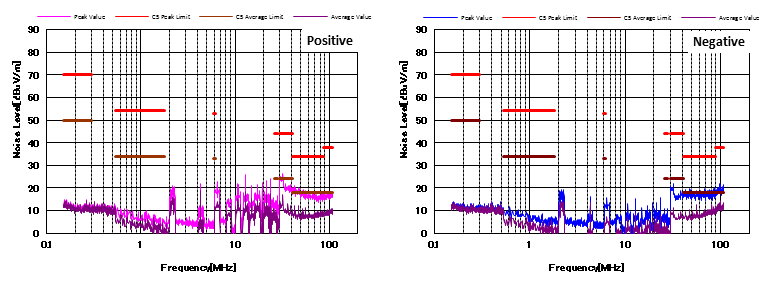

Figure 4 shows the noise characteristics with the addition of CM and DM filters. Compared to Figure 3, the addition of CM filters reduces CM noise by nearly 20dBμV/ m. And EMI performance has also passed the CISPR25 C5 standard.

Figure 4 Noise characteristics under C5 standard (with CM and DM filters)

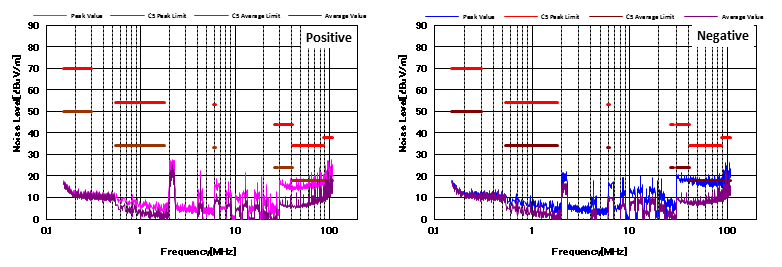

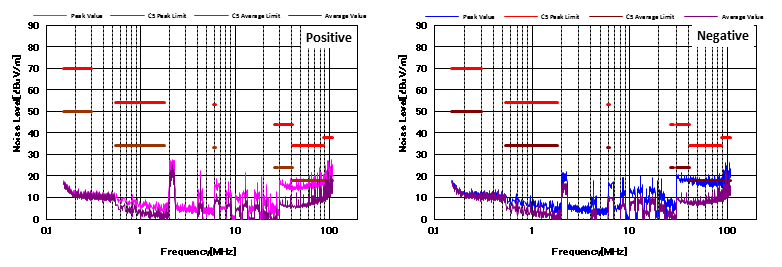

Figure 5 shows the noise characteristics of the CM and DM filters in different layouts, where the filters are the same as in Figure 4. However, compared to Figure 4, the noise in the whole band has increased by about 10dBμV/ m, and the high-frequency noise even exceeds the average of the CISPR25 C5 standard.

Figure 5 Noise characteristics under C5 standard (with CM and DM filters, different layouts)

The difference in noise results between Figures 4 and 5 is mainly due to differences in PCB routing, as shown in Figure 6. In the wiring of Figure 5 (right side of Figure 6), a large area of coppering (GND) surrounds the DM filter and forms some parasitic capacitance with the Vin line. These parasitic capacitors provide an effective low-impedance path for the high-frequency signal bypass filter. Therefore, in order to maximize the performance of the filter, all copper cladding around the filter needs to be removed, as shown in the wiring on the left of Figure 6.

Figure 6 Different PCB routing

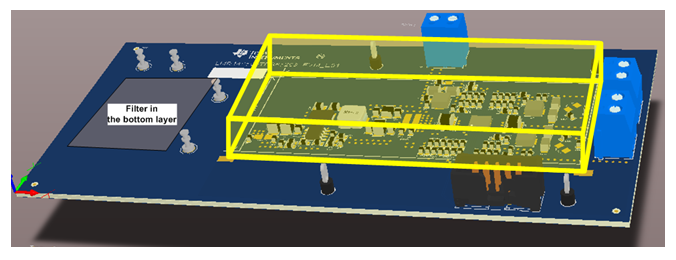

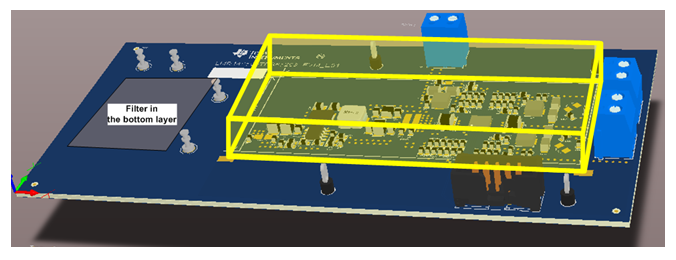

In addition to adding filters, another effective way to optimize EMI performance is to add a mask. This is because a metal shield attached to GND prevents noise from radiating outward. Figure 7 suggests a shielding arrangement. The shield covers exactly all the components on the board. Figure 8 shows the EMI results after adding the filter and mask. As shown in the figure, the noise of the entire frequency band is almost eliminated by the shield, and the EMI performance is very good. This is mainly because the long input leads equivalent to the antenna will couple a lot of radiation noise, and the shield just insulates them. In this design, IF noise is also coupled to the input lead in this way.

FIG. 7 PCB 3D model with shield

Figure 8. Noise characteristics under C5 standard (with CM, DM filter and mask))

Figure 9 also shows the noise characteristics of the band filter and the mask. Unlike Figure 8, the shield in Figure 9 is a metal box that wraps the entire board, with only the input leads exposed. Even with this shield, some radiated noise can still bypass the EMI filter and couple to the power cord on the PCB, which will result in worse noise characteristics than in Figure 8. Interestingly, the noise characteristics of the high frequency bands in Figure 4, Figure 8 and Figure 9 (same layout cabling) are almost the same. This is because after the EMI filter is added, the high-band radiation noise that can be coupled to the input line is almost no longer present.

Figure 9 Noise characteristics under C5 standard (with CM, DM filter and shielded metal box)

In general, the addition of EMI filters or shields can effectively improve EMI performance. But at the same time, the layout of the filter and the placement of the shield need to be carefully considered.

免责声明: 本文章转自其它平台,并不代表本站观点及立场。若有侵权或异议,请联系我们删除。谢谢! Disclaimer: This article is reproduced from other platforms and does not represent the views or positions of this website. If there is any infringement or objection, please contact us to delete it. thank you!

矽源特科技ChipSourceTek |