Lithium-ion battery has the risk of internal short circuit due to the influence of many factors such as material system and manufacturing process. Although lithium-ion batteries have been strictly aging and self-discharge screening at the factory, due to process failure and other unpredictable use factors, there is still a certain probability of failure leading to internal short circuit during use. For the power battery, the lithium-ion battery pack has as many as hundreds or even tens of thousands of batteries, greatly amplifying the probability of the battery pack occurring short. Due to the great energy contained in the power battery pack, the occurrence of internal short circuit is easy to induce vicious accidents, resulting in casualties and property losses. TE's PPTC and HPP-TA family of products provide a possible solution to prevent the occurrence of a serious accident in the event of an internal short circuit in the power battery.

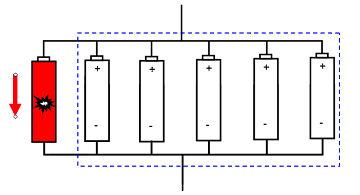

For the parallel lithium-ion power battery module, when one or several batteries have a short time, other batteries in the battery module will discharge it, and the energy of the battery pack will make the temperature of the short battery rise rapidly, which is easy to induce thermal runaway, and eventually lead to the battery fire and explosion. As shown in Diagram 1

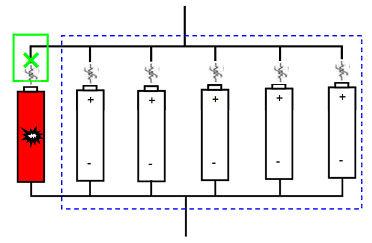

Ideally, if a cell is found to be short and warm, the connection circuit between the cell and the other cells in the module can be cut off. As shown in Figure 2, when TE PPTC or MHP-TA series products are assembled on a single power-saving pool, the TE protection device can effectively block the connection between the internal short-circuit battery and other batteries in the module when the internal short-circuit occurs, and prevent the occurrence of malignant accidents. For a power battery pack with a large number of single cells, the internal resistance consistency of the battery and the device is required to be higher, and the consistency of the device resistance is very good due to the internal bimetallic structure of the HPP-TA, which can greatly meet the requirements for the internal resistance of the battery.

免责声明: 本文章转自其它平台,并不代表本站观点及立场。若有侵权或异议,请联系我们删除。谢谢! Disclaimer: This article is reproduced from other platforms and does not represent the views or positions of this website. If there is any infringement or objection, please contact us to delete it. thank you! |