The brushless DC motor (BLDC) overcomes the congenital defects of the brushless DC motor and replaces the mechanical commutator with the electronic commutator, so the BLDC motor not only has the characteristics of good speed regulation performance of the DC motor, but also has the advantages of simple structure of the AC motor, no commutation spark, reliable operation and easy maintenance. The essence of the brushless DC motor is DC power input, using an electronic inverter to convert direct current into alternating current, with rotor position feedback of the three-phase AC permanent magnet synchronous motor. Compared with the conventional DC motor in performance, it has great advantages and is the most ideal speed regulating motor today.

1, brush DC motor introduction

Before introducing brushless DC motors, let's take a look at brushed motors:

Dc motor is known for its good starting performance, speed regulation performance and other advantages, among which the brush DC motor belongs to a class of DC motor using mechanical commutator, making the driving method simple, its model schematic diagram is shown below.

Dc motor model diagram

DC motor (brush motor) operation diagram

The motor is mainly composed of a stator made of permanent magnet material, a rotor (armature) with a coil winding, a commutator and a brush. As long as A certain DC current is passed into both ends of the brush A and B, the commutator of the motor will automatically change the magnetic field direction of the motor rotor, so that the rotor of the DC motor will continue to operate.

Dc motor has the following disadvantages

The structure is relatively complex, which increases the manufacturing cost;

Easy to be affected by the environment (such as dust, etc.), reducing the reliability of the work;

The commutation will produce sparks, limiting the scope of use;

Easy to damage, increase maintenance costs, etc.

2, brushless DC motor introduction

The "BL" in the BLDC motor means "brushless", that is, the "brush" in the DC motor (brushed motor) is gone.

The brushless DC motor (BLDC) replaces the mechanical commutator with the electronic commutator, so the BLDC motor not only has the characteristics of good speed regulation performance of the DC motor, but also has the advantages of simple structure, no commutation spark, reliable operation and easy maintenance.

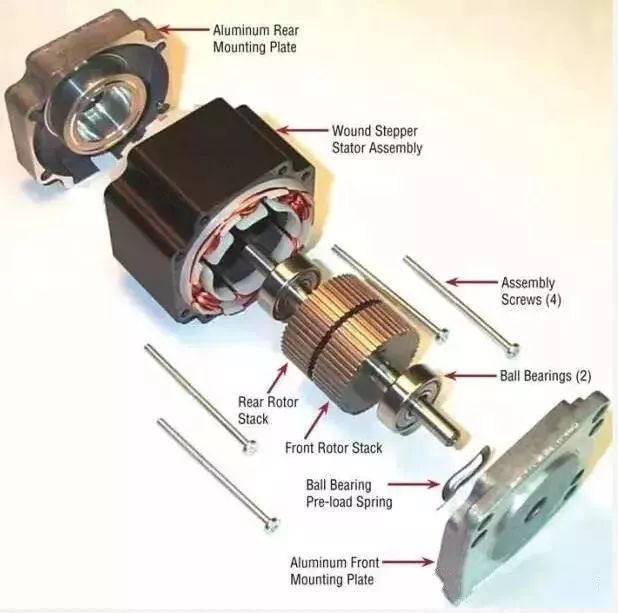

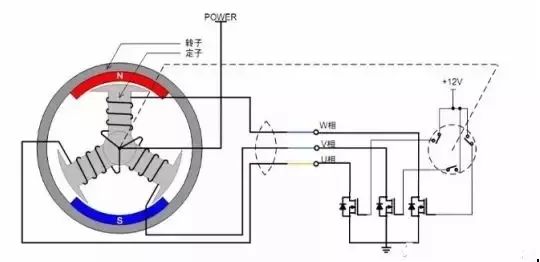

Figure 1: Brushless DC motor model diagram

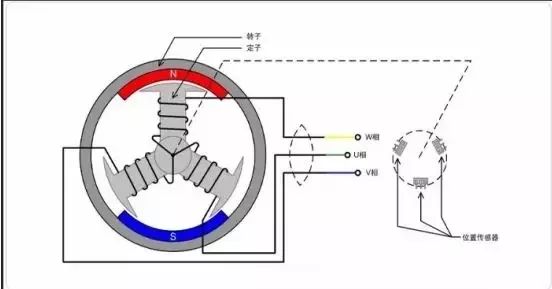

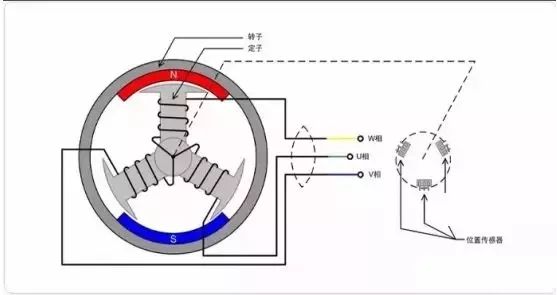

Operation diagram of BLDC motor

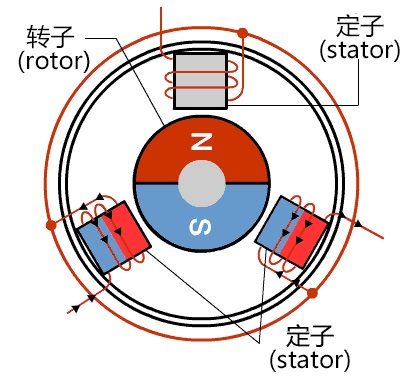

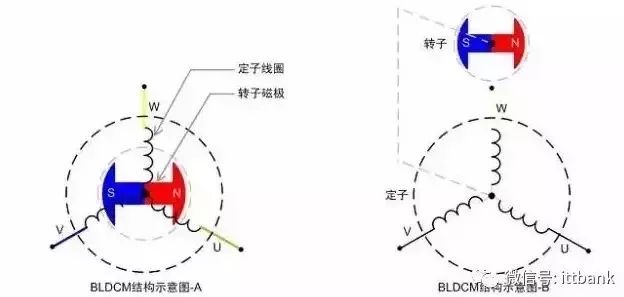

The brushless DC motor mainly consists of a rotor made of permanent magnet material, a stator with coil winding and a position sensor (optional). It can be seen that it has a lot in common with the DC motor, the structure of the stator and the rotor is similar (the original stator becomes the rotor, the rotor becomes the stator), and the connection of the winding is basically the same. However, there is an obvious difference between them in structure: the brushless DC motor does not have the commutator and brush in the DC motor, and is replaced by a position sensor. In this way, the motor structure is relatively simple, reducing the manufacturing and maintenance costs of the motor, but the brushless DC motor can not automatically reverse (phase), at the expense of the cost of the motor controller (such as the same three-phase DC motor, the drive axle of the brushless DC motor needs 4 power tubes, while the drive axle of the brushless DC motor needs 6 power tubes).

FIG. 1 shows one of the low-power three-phase, star-connected, single-pair brushless DC motors with a stator inside and a rotor outside. The structure of another brushless DC motor is just the opposite of this, its stator is outside and the rotor is inside, that is, the stator is a frame composed of coil windings, and the rotor is made of permanent magnet material.

The brushless DC motor has the following characteristics

The brushless DC motor has good external characteristics, which can output large torque at low speed, so that it can provide large starting torque;

The speed range of brushless DC motor is wide, and it can run at full power at any speed.

The brushless DC motor has high efficiency and strong overload capacity, which makes it have excellent performance in the driving system;

The regenerative braking effect of brushless DC motor is good, because its rotor is permanent magnet material, the motor can enter the generator state when braking;

The brushless DC motor has small size and high power density.

The brushless DC motor has no mechanical commutator and adopts a fully enclosed structure, which can prevent dust from entering the motor and has high reliability.

The drive control of brushless DC motor is simpler than that of asynchronous motor.

3, brushless DC motor working principle

The stator of the brushless DC motor is a coil winding armature, and the rotor is a permanent magnet. If only a fixed DC current is given to the motor, the motor can only produce a constant magnetic field, the motor can not rotate up, only real-time detection of the position of the motor rotor, and then according to the position of the rotor to the motor to communicate with the corresponding current, so that the stator produces a rotating magnetic field with uniform changes in direction, the motor can follow the magnetic field to rotate up.

Figure 2 shows the schematic diagram of the rotation principle of the brushless DC motor. For the convenience of description, the coil center of the motor stator is tapped to the motor POWER supply, and the end points of each phase are connected to the power tube. When the position sensor is switched on, the G pole of the power tube is connected to 12V, the power tube is switched on, and the corresponding phase coil is energized. Because the three position sensors with the rotation of the rotor, will turn on in turn, so that the corresponding phase coil is also turned on in turn, so that the direction of the stator generated magnetic field is constantly changing, the motor rotor is also rotating, which is the basic rotation principle of the brushless DC motor - detect the position of the rotor, in turn to each other, so that the direction of the stator generated magnetic field changes continuously and evenly.

Brushless DC motor structure diagram

The stator winding of the motor is mostly made of three-phase symmetrical star connection, which is very similar to the three-phase asynchronous motor. A magnetized permanent magnet is attached to the rotor of the motor, and a position sensor is installed in the motor to detect the polarity of the rotor. The driver is composed of power electronic devices and integrated circuits, etc. Its function is: to accept the start, stop and brake signals of the motor to control the start, stop and brake of the motor; The position sensor signal and positive and negative turning signal are accepted to control the on-off of each power tube of the inverter bridge to generate continuous torque; Receive speed instructions and speed feedback signals to control and adjust the speed; Provide protection and display and more.

Dc motor has a fast response, large starting torque, from zero speed to rated speed can provide rated torque performance, but the advantages of DC motor is its disadvantage, because the DC motor to produce constant torque performance under rated load, the armature magnetic field and rotor magnetic field must be maintained at 90°, which is by carbon brush and commutator. The carbon brush and commutator will produce sparks and toner when the motor is rotating, so in addition to causing component damage, the use of the occasion is also limited. Ac motors have no carbon brush and commutator, are maintenance-free, robust, and widely used, but the characteristics must be achieved with complex control technology to achieve the performance equivalent to DC motors. Today, the rapid development of semiconductors power module switching frequency is much faster, improving the performance of the drive motor. The speed of the microprocessor is also getting faster and faster, which can realize the control of the AC motor in a rotating two-axis cartesian coordinate system, and the appropriate control of the AC motor in the two-axis current component, which is similar to the control of the DC motor and has the equivalent performance of the DC motor.

In addition, many microprocessors have made the functions necessary to control the motor in the chip, and the volume is getting smaller and smaller; Like analog/digital converter (adc), pulse wide modulator (pwm)... Let's wait. The brushless DC motor is an application that electronically controls the commutation of the AC motor and obtains similar characteristics of the DC motor without the absence of the DC motor mechanism.

The drive mode of brushless straightening machine can be divided into a variety of driving modes according to different categories, and they have their own characteristics.

1. According to the drive waveform: square wave drive, this drive mode is convenient to achieve, easy to realize the motor sensorless control;

2. Sine drive: This drive mode can improve the operation effect of the motor and make the output torque uniform, but the realization process is relatively complex. At the same time, this method has SPWM and SVPWM(space vector PWM) two ways, SVPWM effect is better than SPWM.

5, brushless DC motor application field

Application field 1, office computer peripherals, electronic digital consumer goods field.

This is the most popular brushless DC motor, the largest number of areas. For example, common printers, fax machines, photocopiers, hard drives, floppy disk drives, movie cameras, tape recorders, etc., have brushless DC motors in the drive control of their spindles and affiliated movements.

Application field two, industrial control field.

In recent years, due to the large-scale research and development of brushless DC motor and the gradual maturity of technology, the distribution range of its drive system in industrial production has also expanded, and it has gradually become the mainstream of industrial electric motor development. Research and attempts to reduce production costs and improve operating efficiency have achieved significant benefits, and major manufacturers also offer different types of motors to meet the needs of different drive systems. At present, in textile, metallurgy, printing, automatic production lines, CNC machine tools and other industrial production, brushless DC motors are involved.

Application field 3, medical equipment field.

In foreign countries, the use of brushless DC motor has been more common, can be used to drive the artificial heart in the small blood pump; In China, brushless DC motors are used in high-speed centrifuges of high-speed surgical instruments, infrared laser modulators of thermal imagers and thermometers.

Application field four, automotive field.

According to the analysis on the market, the general family car needs 20-30 permanent magnet motors, and each luxury car needs 59, in addition to the core engine, in the wiper, electric doors, car air conditioning, electric Windows and other parts of the motor figure. With the development of the automotive industry in the direction of energy conservation and environmental protection, the motors used must also meet the standards of high efficiency and low energy consumption. The advantages of brushless DC motor such as low noise, long life, no spark interference, convenient centralized control are fully in line with the increasing maturity of its speed regulation technology, the cost performance will be higher and higher, and its application in all aspects of automotive motor drive will be more extensive.

Application field five, the field of household appliances.

"Frequency conversion" technology has been very common, as a symbol of China's home appliances gradually occupied most of the consumer market, "DC frequency conversion" is favored by manufacturers, has gradually replaced the "AC frequency conversion" change trend. This change is essentially the transition of the motor used in home appliances from induction motor to brushless DC motor and its controller, in order to achieve the requirements of energy saving, environmental protection, low noise intelligence and high comfort. The development direction of brushless DC motor is the same as the development direction of power electronics, sensors, control theory and other technologies, it is the product of the combination of a variety of technologies, and its development depends on the innovation and progress of each technology related to it.

免责声明: 本文章转自其它平台,并不代表本站观点及立场。若有侵权或异议,请联系我们删除。谢谢! Disclaimer: This article is reproduced from other platforms and does not represent the views or positions of this website. If there is any infringement or objection, please contact us to delete it. thank you! |