Source: ROHM Author: ROHM

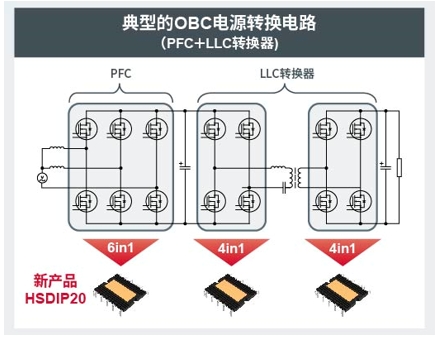

Shanghai, China, April 24, 2025 - ROHM, a globally renowned semiconductor manufacturer headquartered in Kyoto, Japan, today announced the launch of the 4in1 and 6in1 structure SiC plastic-encapsulated module "HSDIP20". This series of products is highly suitable for applications such as PFC*1 and LLC*2 converters of xEV (Electric Vehicle) on-board chargers (hereinafter referred to as "OBC"). The product lineup of HSDIP20 includes six models with a 750V withstand voltage (BSTxxx1P4K01) and seven models with a 1200V withstand voltage (BSTxxx2P4K01). By integrating the basic circuits required in various high-power application circuits into small module packages, the design time for customers can be effectively reduced, and it is also conducive to the miniaturization of power conversion circuits in applications such as OBC.

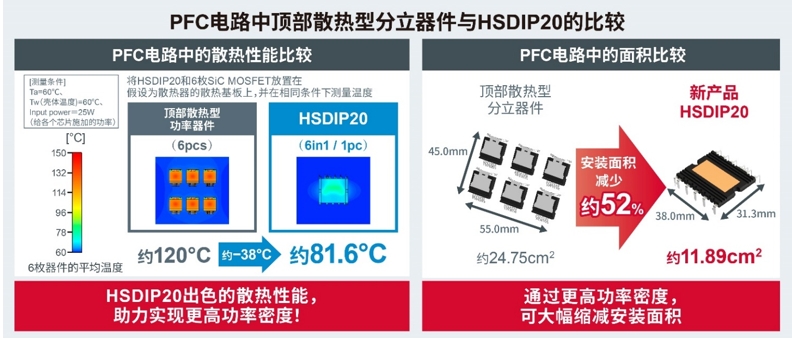

The HSDIP20 is equipped with an insulating substrate with excellent heat dissipation performance, which can effectively suppress the temperature rise of the chip even when operating at high power. In fact, in the commonly used PFC circuit of OBC (using 6 SiC MOSFETs), after comparing the HSDIP20 module with a 6-in-1 structure using 6 top-cooled discrete devices under the same conditions, it was found that the temperature of the HSDIP20 was approximately 38 ° C lower than that of the vertical structure (when operating at 25W). This excellent heat dissipation performance enables the product to handle high current demands with a very small package. In addition, compared with the top-cooled discrete devices, the current density of HSDIP20 reaches more than three times. Compared with the DIP modules of the same type, the current density is as high as more than 1.4 times, reaching the advanced level in the industry. Therefore, in the above-mentioned PFC circuit, the installation area of HSDIP20 can be reduced by approximately 52% compared to the top-cooled discrete devices, which is highly conducive to the miniaturization of power conversion circuits in applications such as OBC.

The new product has been temporarily put into mass production at a scale of 100,000 units per month since April 2025 (the sample price is 15,000 yen each, excluding tax). The production bases of the previous process are ROHM Apollo CO., LTD. (Chikugo Factory, Fukuoka Prefecture, Japan) and the Miyazaki Factory of Blueshi Semiconductor (Nishizaki Prefecture), and the production base of the subsequent process is ROHM Integrated Systems (Thailand) Co., Ltd. (Thailand). For samples or to learn more about related matters, please contact a ROHM sales representative or inquire through the "Contact Us" section on the ROHM official website.

<Development Background>

In recent years, in order to achieve a carbon-free society, the popularization speed of electric vehicles has further accelerated. In the field of electric vehicles, to extend the vehicle's driving range and increase the charging speed, the batteries adopted are accelerating towards higher voltage levels. Meanwhile, the demand for enhancing the output power of OBC and DC-DC converters is becoming increasingly prominent. On the other hand, the market also demands that these applications be miniaturized and lightweight, with the core being to enhance power density. At the same time, there is an urgent need for technological breakthroughs in improving heat dissipation performance, which affects the increase in power density. The HSDIP20 developed by ROHM has solved this technical problem that discrete structures are increasingly difficult to handle, which helps electric powertrain systems achieve higher power output and smaller size. In the future, ROHM will continue to develop SiC module products that combine miniaturization and high efficiency, and at the same time be committed to developing automotive SiC IPMs that can achieve smaller volume and higher reliability.

<Product lineup>

<Application example>

Power conversion circuits such as PFC and LLC converters are also widely used in the primary side circuits of industrial equipment. Therefore, HSDIP20 can also provide support for the miniaturization of application products in fields such as industrial equipment and consumer electronics.

◇ Vehicle-mounted equipment

On-board charger (OBC), DC-DC converter, electric compressor, etc

◇ Industrial equipment

EV charging piles, V2X systems, AC servers, server power supplies, PV inverters, power regulators, etc

<Support information>

ROHM has the equipment to conduct motor testing within the company and can provide strong support at the application level. To accelerate the evaluation and application of the HSDIP20 product, ROHM also offers a variety of support resources, including a rich range of solutions from simulation to thermal design, to help customers quickly adopt the HSDIP20 product. In addition, ROHM also offers two types of evaluation kits, one for dual-pulse testing and the other for three-phase full-bridge testing, which support evaluation under conditions close to actual circuit conditions. For detailed information, please contact a ROHM sales representative or inquire through the "Contact Us" section on the ROHM official website.

<About "EcoSiC?" Brand>

EcoSiC? It is a component brand that adopts silicon carbide (SiC), which has attracted much attention in the field of power components due to its superior performance compared to silicon (Si). From wafer production to manufacturing processes, packaging and quality management methods, ROHM has been independently developing the necessary technologies for upgrading SiC products. In addition, ROHM adopts a consistent production system in its manufacturing process and has established its position as an advanced enterprise in the SiC field.

[Note] EcoSiC? It is a trademark or registered trademark of ROHM Co., Ltd.

*1) PFC (Power Factor Correction/ Power Factor Correction)

A circuit that improves the power factor by enhancing the input power waveform in the power supply circuit. The use of PFC circuits can make the input power approach a sine wave (power factor =1), thereby improving the power conversion efficiency. PFC circuits typically use diodes for rectification, but OBCs usually employ active bridge rectification implemented with MOSFETs or bridge-free PFC. This is because the switching loss of MOSFETs is lower. Especially in high-power PFC, the use of SiC MOSFETs can reduce heat generation and power loss.

*2)LLC converter

A resonant DC-DC converter capable of achieving high-efficiency and low-noise power conversion. The basic structure of its circuit is composed of two inductors (L) and one capacitor (C), and thus it is called an LLC converter. By forming resonant circuits, switching losses can be significantly reduced, making it highly suitable for high-efficiency application scenarios such as OBC, industrial equipment power supplies, and server power supplies.

免责声明: 本文章转自其它平台,并不代表本站观点及立场。若有侵权或异议,请联系我们删除。谢谢! Disclaimer: This article is reproduced from other platforms and does not represent the views or positions of this website. If there is any infringement or objection, please contact us to delete it. thank you! |