Source: ON Beauty Author: Wonhwa Lee, Product Line Manager

Everything is stored in the cloud these days, but where exactly is the cloud?

The answer is the data center. Our insatiable demand for pictures, video and other content is driving the data center industry to flourish.

According to the International Energy Agency (IEA), the rapid development of the artificial intelligence (AI) industry is leading to a surge in the demand for power in data centers. Data center power consumption is expected to more than double in the three years from 2022 to 2025. This not only increases operating costs, but also puts enormous pressure on an already overburdened and aging power infrastructure that is in dire need of massive investment upgrades.

As data center power consumption increases dramatically, there is an even more urgent need for power semiconductors that can efficiently convert power. This demand is growing on the one hand to reduce operating costs and on the other to reduce greenhouse gas emissions in order to achieve the goal of net zero emissions. In addition, the industry is also constantly pursuing lower cost, smaller size power systems.

Heat dissipation is another major challenge for data centers. It is estimated that most data center cooling systems today account for more than 40% of electricity consumption. In fact, for power efficiency, the wasted energy is mainly lost in the form of heat, which in turn needs to be discharged through the air conditioning system of the data center. Therefore, the higher the power conversion efficiency, the less heat generated, and correspondingly, the lower the cost of electricity in terms of heat dissipation.

AC-DC conversion requirements for data centers

Let's take a more detailed look at the needs of data center power systems and how device vendors are addressing these challenges. Power density in data centers is accelerating, and power supply (PSU) vendors are working to increase the power capabilities of standard 1U racks (Figure 1). About a decade ago, the average power density per rack was about 4 to 5 kW, but today's hyperscale cloud companies, such as Amazon, Microsoft, or Facebook, typically require a power density of 20 to 30 kW per rack. Some professional systems are even more demanding, requiring a power density of more than 100kW per rack.

However, the challenge is not only to improve overall energy efficiency, the power supply must also meet the specific needs of the data center industry. For example, all AI data center Psus should meet the strict Open Rack V3 (ORV3) basic specifications.

Recently, server rack providers introduced a new AC-DC PSU with a nominal input range of 200 to 277 VAC and an output of 50 VDC, which is ORV3 compliant. The standard requires a peak efficiency of more than 97.5% at 30% to 100% load conditions and a minimum efficiency of 94% at 10% to 30% load conditions.

Topology selection of the server rack power supply

The power factor correction (PFC) stage is a key component of AC-DC conversion in PSU and is important for achieving high energy efficiency. The PFC stage is responsible for shaping the input current to maximize the ratio of useful power to total input power. To meet electromagnetic compatibility (EMC) standards in regulations such as IEC 61000-3-2 and ensure compliance with ENERGY STAR? Such as energy efficiency specifications, PFC design is also key.

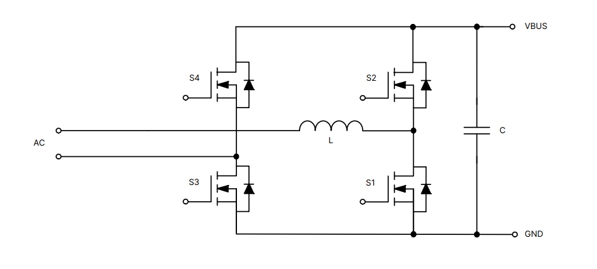

For many applications, such as data centers, it is best to choose a "totem pole" PFC topology to design the PFC level. This topology is typically used for PFC functional blocks in 3 kW to 8 kW system power supplies in data centers (Figure 2). The Totem Pole PFC class is based on MOSFETs and improves the efficiency and power density of AC power supplies by removing bulky and lossless bridge rectifiers.

Compared to silicon MOSFETs, SiC MOSFETs offer better performance and energy efficiency, are robust and reliable, perform better at high temperatures, and can operate at higher switching frequencies.

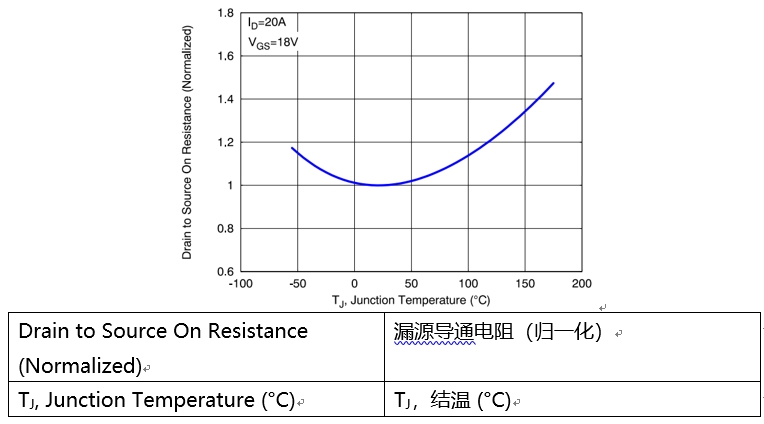

SiC MOSFETs store less energy (EOSS) in the output capacitance than silicon-based superjunction MOSFETs, which is critical to achieving low load goals because switching losses at the PFC-level are primarily from devices with relatively high EOSS and gate charges. The lower EOSS greatly reduces the energy loss during the switching process, thereby improving the energy efficiency of the Totem pole PFC fast bridge arm. In addition, because SiC devices have excellent thermal conductivity, equivalent to three times that of silicon-based devices, SiC MOSFETs have a better positive temperature coefficient RDS(ON) compared to silicon-based superjunction MOSFETs.

The following figure shows the relationship between the on-resistance of a 650V SiC MOSFET and junction temperature. (The on-resistance at junction temperature 175℃ is 1.5 times higher than that at room temperature.)

In Totem pole PFC slow bridge arm function block and LLC function block, the on-off loss accounts for most of the total power loss. SiC MOSFETs have lower RDS(ON) at higher junction temperatures, helping to improve system energy efficiency.

Thanks to small increases in RDS(ON) at high temperatures and excellent EOSS, SiC MOSFETs excel in totem pole PFC topologies, helping to improve energy efficiency and reduce energy loss.

The new SiC MOSFET technology delivers superior system energy efficiency

onsemi's 650V M3S EliteSiC MOSFETs (including NTBL032N065M3S and NTBL023N065M3S) offer superior switching performance and significantly improved system energy efficiency at the PFC and LLC levels. The M3S EliteSiC technology far outperforms its predecessor with a 50 percent reduction in gate charge, 44 percent reduction in EOSS and 44 percent reduction in charge stored in output capacitors (QOSS). When used in PFC-class hard switching topologies, excellent EOSS performance further improves system energy efficiency under light loads. In addition, lower QOSS simplifies the design of resonant energy storage inductors for LLC-class soft switching topologies.

Thanks to superior switching performance and energy efficiency, the M3S EliteSiC MOSFETs emit less heat. In addition to helping to reduce heat dissipation requirements in the data center, the device also operates at lower temperatures in PFC and DC-DC functional blocks with high operating frequencies, such as in wall-mounted DC charging piles for electric vehicles (EVs).

In addition, at the same voltage level, the M3S EliteSiC MOSFETs have better gate charge Qg and lower gate drive losses. At the same time, excellent Qgs and Qgd also help reduce switching on and off losses. In the LLC function block, the output capacitor needs to be charged when the VDS transitions from the off state to the diode on-state. In order to accomplish this process quickly, a low transient output capacitance (COSS(TR)) must be used. Transient COSS is important here because it minimizes cycle losses for resonant energy storage and shorens the LLC dead time, thereby reducing cycle losses on the primary side. Low on-resistance minimizes on-loss as much as possible, and low EOFF helps to further reduce switching losses. Overall, improving system energy efficiency is a key performance criterion, making SiC MOSFETs the preferred solution for data center PFC and LLC levels.

The new EliteSiC MOSFETs are also ideal for energy infrastructure applications such as photovoltaic (PV) generators, energy storage systems (ESS), uninterruptible power supplies (UPS) and electric vehicle charging stations. Design engineers can use the M3S EliteSiC MOSFETs to reduce the overall system size, thereby helping to increase the operating frequency. From a system perspective, the M3S EliteSiC MOSFETs help design engineers reduce system costs compared to silicon-based 650 V super junction MOSFETs.

In summary, the new EliteSiC MOSFETs are comparable to super junction MOSFETs ON the market in terms of cost, EMI, high temperature operation and switching performance based on the same RDS(ON). The 650V M3S EliteSiC MOSFETs in the same package achieve lower RDS(ON) than the super junction MOSFETs, helping to improve system energy efficiency in LLC topologies. Compared with other silicon-based alternative devices, its outstanding advantage is that the switching loss is significantly reduced.

conclusion

This article briefly explores the higher standards that the increasing power demand of hyperscale data centers puts forward for efficient power conversion. Artificial intelligence is poised to revolutionize the world, and in order for our existing power grids to meet the demands of the explosion of AI-powered cloud computing, we urgently need to improve energy efficiency.

The use of SiC MOSFETs can significantly improve the energy efficiency of the PFC and LLC grades. On's 650 V M3S EliteSiC MOSFETs enable significant improvements in PFC and LLC-level energy efficiency in hyperscale data centers. With lower gate charges, EOSS and QOSS, the 650 V M3S EliteSiC MOSFETs can improve energy efficiency and simplify hard switch topology design in the PFC and LLC levels, helping to reduce power consumption and reduce operating costs.

免责声明: 本文章转自其它平台,并不代表本站观点及立场。若有侵权或异议,请联系我们删除。谢谢! Disclaimer: This article is reproduced from other platforms and does not represent the views or positions of this website. If there is any infringement or objection, please contact us to delete it. thank you! |