ChipSourceTek-CST6118 Single channel brush DC motor drive chip solution

Ⅰ、Chip overview

ChipSourceTek-CST6118 It is a high-performance single-channel written DC motor driver chip designed for low power consumption and high efficiency motor control scenarios. Its built-in full-bridge power MOS drive architecture, support forward/reverse/stop/brake function, with 1.8A continuous output current and 2.5A peak current capabilities, suitable for a wide range of small motor drive needs. The chip integrates overtemperature protection (TSD) and simplifies the peripheral circuitry through an optimized full-bridge drive design, significantly reducing system costs.

Ⅱ、Core characteristic

Driving ability

- Maximum continuous output current:1.8A

- Peak output current: 2.5A (transient)

- On-resistance: 0.4Ω (@1A current)

Working conditions

- Wide voltage input range:1.5V~7.2V

- Very low static power consumption: <1μA (typical value 0.1μA)

- Encapsulation form:SOP-8

Functions and controls

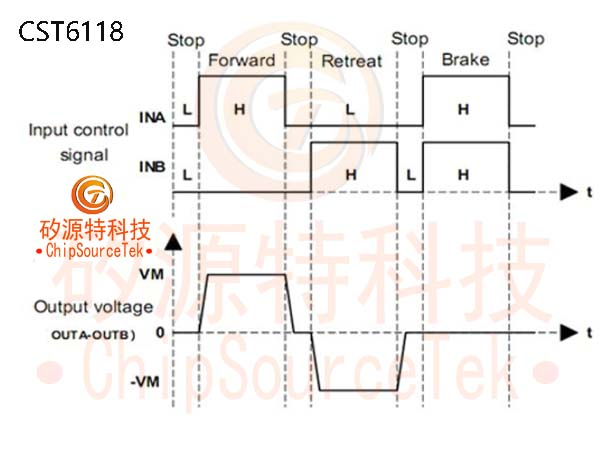

- Support motor (forward, reverse, stop, brake ) four mode control

- Built-in Thermal protection with hysteresis (TSD) to prevent overheating damage

- Full bridge drive architecture, eliminate the peripheral filter circuit, simplify the design

Ⅲ、Typical application scenario

- Consumer electronics:Electric toothbrush, electronic lock, remote control car, adult sex toys

- Intelligent hardware :Car mount, toy motor drive (e.g. 4WD, model)

- Industrial equipment:Small automation equipment, low power actuator

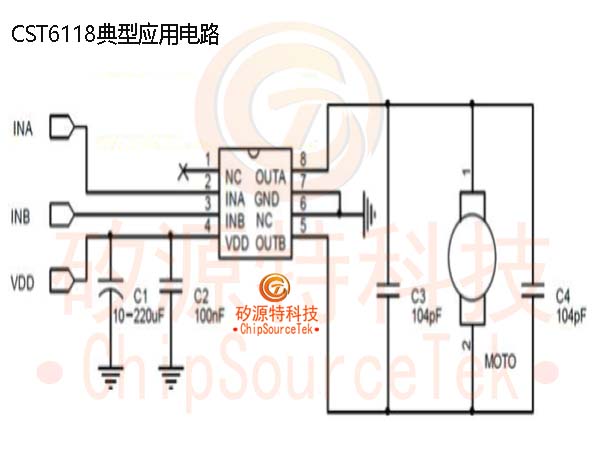

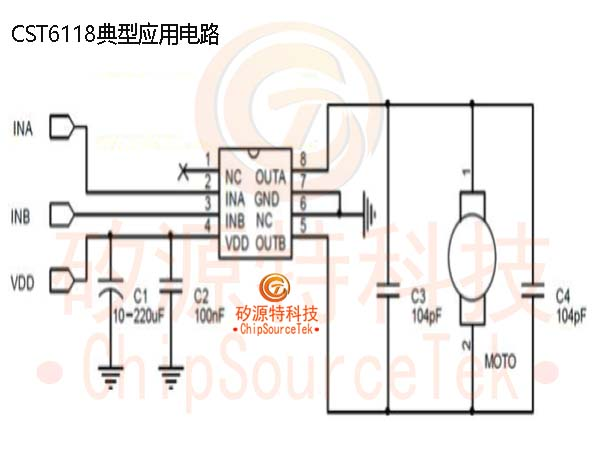

Ⅳ、Typical application circuit design

circuit diagram description

- Motor bypass capacitance:The C4/104P capacitors must be connected in parallel at both ends of the motor. If the motor is not connected, reserve a capacitor position on the PCB.

- Peripheral reduction:Compared with traditional solutions, C1, C2 and C3 capacitors can be omitted to reduce the number of components and reduce costs.

Pin definition (SOP-8 package)

1 VCC Power input(1.5-7.2V) 2 IN1 Control signal input 1 3 IN2 Control signal input 2 4 GND Ground connection 5-8 OUT1~OUT2The motor drives the output

Ⅴ、Design advantage

- High integration :Full bridge drive architecture reduces peripheral components and saves more than 30% PCB area.

- Low power design:Static current <1μA, suitable for battery-powered scenarios (such as wireless devices).

- Strong anti-interference:Built-in filter and thermal protection, suitable for complex electromagnetic environment.

- Cost advantage :By omitting the filter capacitor, the BOM cost is reduced by about 15%.

Ⅵ、Packaging and production information

- Package specification :SOP-8 (Patch Package)

- Recommended welding conditions:Reflow peak temperature ≤260℃, time ≤10 seconds.

- Storage environment:-40℃~125℃, humidity <60%RH (non-condensing).

Ⅶ、Technical support

- furnish Typical waveform diagram(Start/brake/reverse rotation timing)and PCB Layout Reference。

- Supports customized parameter adjustment (such as current limit and protection threshold).

Remarks:The preceding solution can be optimized based on specific application scenarios. For complete technical documents or sample applications, contact the supplier.