Source: ON By Arndt Schubel

Our world is becoming smarter and more connected, with buildings and factories being automated like never before. To ensure that these new systems operate effectively, reliable information communication is essential - not only within industrial control panels, but also between the various devices spread throughout the premises.

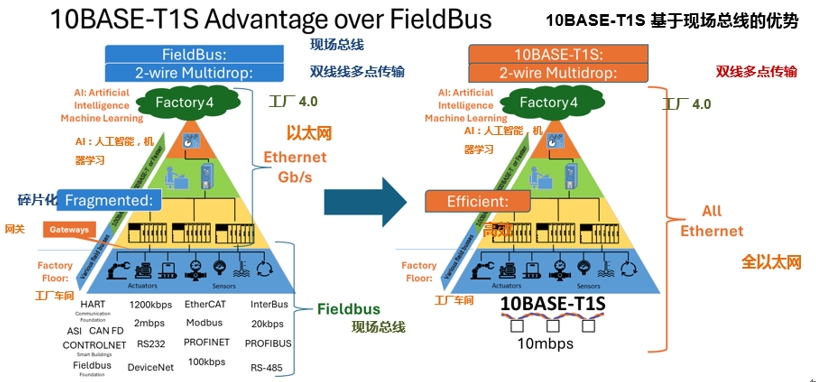

Until recently, industrial networks were complex and might have required the use of a variety of protocols and gateways. This can be expensive and unreliable, making it difficult to ensure the connectivity it deserves.

However, with the advent of 10BASE-T1S Ethernet, a revolution is taking place. This innovative standard replaces traditional fieldbus technology, providing multiple benefits to modern network environments and eliminating the need for gateways.

A range of devices that support the new standard, such as On Midea Industrial 10BASE-T1S Ethernet controllers, provide a reliable and efficient single-chip solution for connecting twisted pair (TP) cables.

Reliable connections for industrial applications

Although the distances within industrial cabinets are relatively short, it is extremely challenging to provide reliable connections in industrial applications, especially due to the large amount of electrical noise. Large switchboards, motors, and many other high-current/high-voltage devices generate a degree of electromagnetic interference that can disrupt network communications.

In office applications, slow data transfer due to outages can be frustrating or inconvenient. However, in industrial applications, the timely transmission of data is crucial, especially from remote sensors that control the operation of machines. If the data is delayed or incorrect, process parameters may be violated, or worse, production equipment may be damaged.

For the same reason, the timely transmission of data becomes particularly important. This does not apply to protocols that negotiate bus access based on random timeouts.

Network infrastructure is often described as a "stack" with the physical implementation (cabling/media) at the bottom and increasingly complex software on top. In Factory 4.0 applications, artificial intelligence (AI), machine learning (ML), planning, execution, automation, tracking, inventory control, supervisory control, and more are at the top. The lowest level (physical layer) is the factory floor, where edge nodes including robots, actuators, motion sensors, and valves perform physical manufacturing work, often covering multiple assembly lines.

In order for it to work as a unified network, gateways need to be installed between the Ethernet portion and other protocols, which leads to communication fragmentation and increases cost and complexity. A new Ethernet will significantly enhance edge connectivity in smart building and factory applications.

The approval of the IEEE 802.3cg specification in 2019 brought 10BASE-T1S. The standard is based on standard Ethernet with several important differences, providing throughput of 10Mb/s and multi-point operations with deterministic conflict handling mechanisms. The standard can be run on unshielded single twisted pair (SPE) wires, greatly simplifying the installation process and reducing costs.

Deterministic operations are critical for real-time systems, which must transmit information within a known time. The CSMA/CD (carrier monitor Multiple Access/collision detection) used by traditional Ethernet uses a random time period, so the communication time cannot be guaranteed deterministic.

10BASE-T1S uses a new system called PLCA (Physical Layer Collision Avoidance) to avoid data collisions on the bus. Under PLCA, 2.0μs beacons are sent by node 0 (coordinator) to synchronize the various nodes in the network. Then, node 0 gets a transmission opportunity. If no data is transmitted, the opportunity is passed to node 1 within the default standard 3.2 microseconds. So the cycle repeats, each node in turn gets a send opportunity. At the end of the cycle, the coordinator sends a beacon signal and a new cycle begins. If a node attempts to transmit more data than the allowed frame size, the "jabber "function interrupts the transmission and passes it on to the next node, ensuring that the bus does not get blocked.

By using PLCA, the worst-case media access latency can be calculated by multiplying the current number of nodes by the maximum network frame size, which can be adjusted.

Many industrial applications are exposed to harsh electromagnetic environments where switchgear, motors and other large equipment generate radiation and conducted noise. Despite using unshielded twisted pair, 10BASE-T1S offers excellent electromagnetic compatibility (EMC) performance compared to existing Ethernet protocols.

This is partly due to the use of PLCA. Because the bus is known to be conflict-free, the physical layer receiver is able to use complex algorithms to detect or recover signals when there are high levels of noise in the environment.

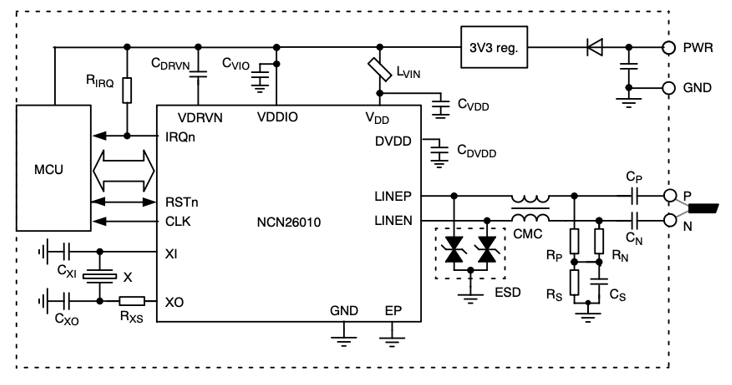

With the introduction of the 10BASE-T1S protocol, new devices are optimized for 10BASE-T1S, enabling designers to take full advantage of the new features. For example, On's NCN26010 is an IEEE 802.3CG-compliant Ethernet transceiver that integrates a Media Access controller (MAC), PLCA harmonic subelayer (PLCA-RS), and 10BASE-T1S physical layer for industrial multipoint Ethernet. The device has built in all the physical layer functions needed to send and receive data over a single unshielded twisted pair.

In addition, the NCN26010 features Enhanced Noise resistance (ENI), which increases noise resistance to levels beyond those required by the 10BASE-T1S specification. This greatly improves network performance in noisy industrial environments.

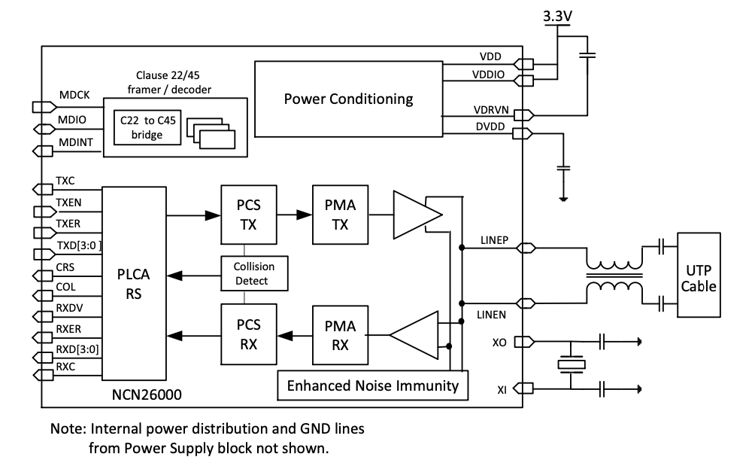

On Semiconductor announced the NCN26000 10BASE-T1S Ethernet transceiver (PHY) in April 2024, designed specifically for industrial Ethernet. It shares many features with the earlier NCN26010, including the IEEE802.3cg standard and the ability to achieve a multipoint, half-duplex 10 Mb/s data transfer rate via the SPE.

The NCN26000 has an IEEE802.3-compliant Media Independent Interface (MII) that can be connected to any MAC with CSMA/CD half-duplex capability with CRS and COL pins, and the MII can also be used to configure and monitor devices (known as MDIO).

Both devices integrate On's ENI capabilities to significantly improve the performance of 10BASE-T1S multipoint applications in electrically noisy environments. When tested in the lab, both devices easily exceeded the minimum requirement of eight nodes within 25 meters. In fact, further tests showed that ENI could support about 40 nodes at 25 meters, 16 nodes at 50 meters, and six nodes at 60 meters, easily exceeding the requirements of the IEEE specification.

Application and deployment scenarios

10BASE-T1S not only features deterministic operation, it is based on unshielded single pair Ethernet (SPE) cables, and the deployment cost is relatively low. The lower cost and simpler integration of 10BASE-T1S helps bring a wide range of possibilities to applications that were previously limited by budget or packaging. One example is in complex industrial automation, where previously separate sensor nodes are upgraded to connect to a centralized network system. Previously available connectivity methods can be too expensive or difficult to integrate, while 10BASE-T1S overcomes these barriers. Similar cost and packaging challenges are encountered during the design of new robotics or automation solutions, and 10BASE-T1S can once again help achieve greater interconnectivity without compromising performance or increasing budgets.As the field of building automation continues to evolve, 10BASE-T1S can be used in applications such as control panels, human machine interfaces (HMI), sensors, actuators and lighting to provide a high-speed and reliable backbone for the entire building.

In industrial applications, performance and cost are important, and noise resistance is particularly important. Here, 10BASE-T1S can be used to connect from the control cabinet to programmable logic controllers (PLCS), sensors, contactors, and any other device that is appropriately equipped with a 10BASE-T1S interface.

conclusion

Until recently, because the various protocols commonly used by edge devices were not compatible with each other, the network of an automated factory required the installation of many gateways between the edge devices and the main Ethernet network. Typically, these fieldbus protocols include HART, RS-485, Mod-bus, DeviceNet, Profi-Bus, and CAN, each requiring its own gateway. This adds cost and complexity, especially as each gateway requires software updates and maintenance.

With the advent of 10BASE-T1S, industrial networks have been simplified and performance has been improved. The presence of a gateway is no longer required, and edge connectivity has shifted from a sub-1MB /s fieldbus protocol to a 10Mb/s deterministic Ethernet.

On has a range of products for the new protocol, including two controllers that comply with the IEEE 802.3cg standard. With their unique ENI capabilities, they can be successfully deployed in the noisiest environments and can even connect up to 40 nodes on a 25-meter line, four times the standard requirement.

免责声明: 本文章转自其它平台,并不代表本站观点及立场。若有侵权或异议,请联系我们删除。谢谢! Disclaimer: This article is reproduced from other platforms and does not represent the views or positions of this website. If there is any infringement or objection, please contact us to delete it. thank you! |