矽源特ChipSourceTek-CST6115重塑小型电机控制

Breakthrough Drive Solution: How does ChipSourceTek-CST6115 Reshape Small Motor Control with 12V/4A Performance?

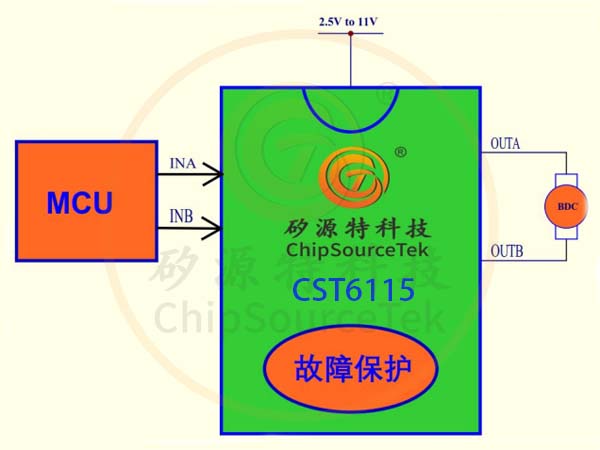

I、Core parameters and industry positioning

ChipSourceTek-CST6115 is a highly efficient driver chip specifically designed for brushed DC motors. Its wide voltage operating range of 2.5V to 12V (with a maximum withstand voltage of 15V) covers a wide range of scenarios from portable devices to industrial control. This chip offers a continuous operating current of 2.1A and a peak transient output capability of 4A, meeting the high-load requirements such as motor start and stop, and locked rotor. As an innovator in the field of motor driver chips, ChipSourceTek-CST6115 has been successfully applied to high-end devices such as smart homes, robot joints, and electronic locks, achieving precise bidirectional control of motors through an H-bridge architecture.

Ii. Analysis of the Eight Core Technological Advantages

Intelligent power topology

It adopts a four-channel N-MOSFET H-bridge drive architecture and significantly reduces power consumption through a low on-resistance (Rds(on)) design. Compared with traditional discrete solutions, the integrated design reduces the PCB footprint by 70% and supports a PWM speed regulation response up to 10kHz.

Dynamic current management

The unique current Decay Mode can intelligently adjust the energy release of the motor winding. When a sudden load change is detected, the chip automatically switches between fast attenuation and slow attenuation modes to avoid mechanical vibration caused by speed fluctuations.

Triple safety protection

Overcurrent protection (OCP) : Real-time monitoring of MOSFET current, and immediate shutdown triggered by a 4A peak threshold

Under-voltage lockout (UVLO) : Forces into sleep mode when the input voltage drops below 2.3V to prevent logical errors

Overheat shutdown: Protection is activated when the junction temperature exceeds 150℃ and automatically recovers after cooling

Revolution in Energy Consumption Control

Support μ A-level sleep mode: When the dual logic input pins (IN1/IN2) remain at A low level for more than 1ms, the quiescent current drops to the microampere level, extending the standby time of battery-powered devices by five times.

Iii. In-depth adaptation to industry application scenarios

- In the field of smart door locks: Utilizing 12V voltage compatibility to directly drive the lock tongue motor, the peak current ensures that the opening and closing actions are completed within 0.3 seconds

Service robot joint: 2.1A continuous current supports high-torque servo, PWM speed regulation achieves 0.1° precise positioning

Medical equipment pump: Reduce electromagnetic interference (EMI) below FCC Class B standard through the ripple suppression scheme on page 8 of the PDF data sheet

Iv. Design Practice Guidelines

Key points of layout

- The length of the power loop path (VM-GND) should be less than 10mm to avoid voltage spikes caused by parasitic inductance

- The heat dissipation pads must be connected to a copper foil area of ≥4×4cm² (thermal resistance θja < 40℃/W).

Typical troubleshooting

If the motor experiences starting and stopping jitter, it is necessary to check whether the IN1/IN2 pins meet the requirements

①PWM duty cycle > 15% (maintaining the minimum drive voltage)

② Rise/fall time < 500ns (to avoid MOSFET half-conduction)

五、Competitive performance comparison

| Parameter | CST6115 | Industry average | Margin of advantage |

|-----------------|---------------|-------------|----------|

| Operating voltage range | 2.5V-12V | 3V-9V | +33% |

| Peak driving capability | 4A | 2.8A | +43% |

| Sleep current | <1μA | 50μA | -98% |

| Protection response time | 200ns | 1μs | Five times faster |

Get the complete technical solution immediately

As the preferred choice for enterprise-level motor driver chips, CST6115 has passed the IEC 62368-1 safety certification. Click to download the authoritative data manual: CST6115 Complete Specification sheet, to obtain the motor drive parameter calculation tool, reference design schematic diagram and EMC optimization plan. Contact the Silicon Source technical support team to apply for free samples and customized driver solution evaluations.